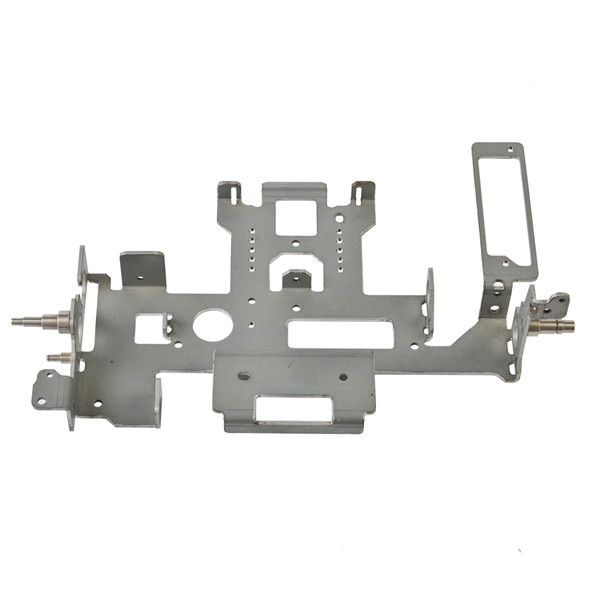

Tag: custom aluminum box

-

What Types of Patterned Aluminum Sheet ?

Patterned aluminum sheet is a high-cost modern material with many types, which is very widely used in furniture, such as refrigerators, air conditioners, carriages, platforms, screen skeletons, various suspension beams, etc. According to the aluminum plate pattern can be divided into the following types. Five bars aluminum alloy pattern plate because the pattern on the […]

-

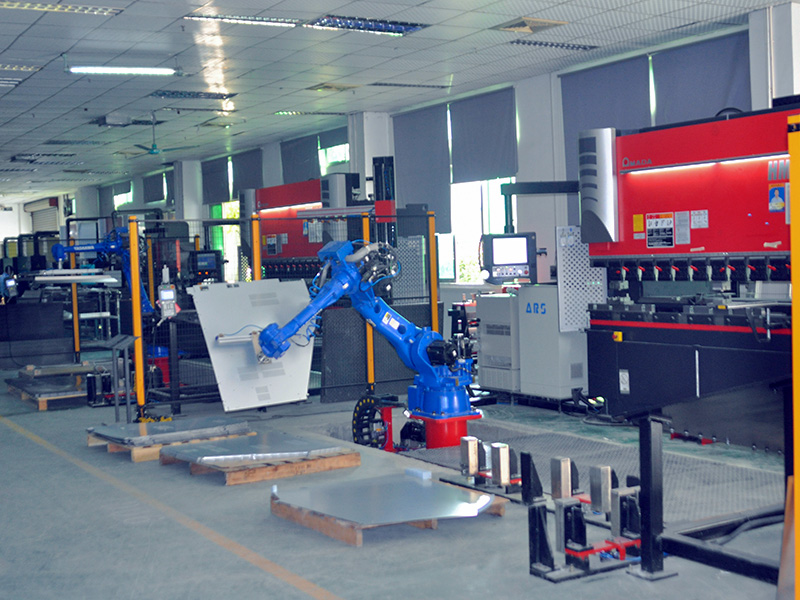

What is Welding Robot used for?

The welding robot can process complex and precise metal workpieces, and the welded workpieces are flat without grinding, polishing or only simple treatment, and no filler material is needed for welding, saving production costs. It can easily carry large workpieces and process them even in narrow working spaces. It has good welding quality, high efficiency, […]

-

What is the Advantage of Aluminum Box Compared with Iron Box?

Aluminum boxes can be divided into ordinary boxes and easy-to-open cans, easy-to-open cans used for beer and beverages believe that we are very much in contact with, the amount is also very large, the global annual calculation of more than 10 billion easy-to-open cans. Aluminum boxes are used as ordinary boxes and are becoming popular […]

-

What is the Sheet Metal Welding Process like?

Sheet metal welding has argon arc welding, spot welding, carbon dioxide shielded welding, manual arc welding, etc. Spot welding should first consider the location of the sheet metal workpiece to be welded, and consider doing positioning tooling to ensure the spot welding position is accurate when mass production. In order to weld firmly, hitting the […]

-

How to Choose the Aluminum Box Manufacturer?

A good sheet metal manufacturer can be examined from many aspects, near if you can visit the field, far if you can judge from the Internet, his customer reviews, scale, years of experience, made in kind, the manufacturers he has worked with and so on. If you want to find such a custom aluminum box […]

-

What is Outdoor EV Charger Enclosure?

Outdoor EV charger enclosures function similarly to gas pumps in gas stations and can be fixed to the floor or wall, installed in public buildings (public buildings, shopping malls, public parking lots, etc.) and residential community parking lots or charging stations, and can charge various models of EVs depending on their voltage levels. Outdoor EV […]

-

What is the General Tolerance for Sheet Metal Fabrication?

Sheet metal processing is the most commonly used metal processing method nowadays. In the process of parts processing, the size of produced sheet metal parts cannot be absolutely accurate due to various factors such as processing accuracy of machinery and equipment, die wear and tear, processing errors, etc. In order to ensure the availability of […]

-

Sheet Metal Design Basics

With the widespread use of sheet metal, sheet metal design has become a very important part of the product development process. What should I pay attention to in sheet metal design? Sheet metal design generally has the following design points. (1) Sheet metal design should first pay attention to the relationship between the sheet metal […]

-

Sheet Metal Manufacture and Quality Control

Sheet metal parts are important components of injection molding machines, not only for their complex structure but also for their beautiful appearance and safety protection. The main processes are: cutting, shearing, punching, folding, welding, splicing, molding, spraying, etc. It is the last process of injection molding machine assembly. Due to the complicated process, the outsourcing […]

-

How to Determine the Bending Radius of Sheet Metal? What is the Relationship with the Plate Thickness?

The bending radius of a sheet is a value required in the sheet drawing and it is difficult to determine its size in the actual process. In fact, the bending radius of sheet metal is related to the thickness of the material, the pressure of the bending machine and the width of the lower die […]