Tag: custom aluminium box

-

What are the Advantages of Customized Metal Welding Processing?

If you need to customize some metal products, such as parts, components, frames, etc., then custom metal welding processing must be your choice! Compared with traditional metal manufacturing methods, custom metal welding processing has the following advantages: 1. Flexibility: Custom metal welding processing can be customized according to the customer’s needs, so it has a […]

-

Large Chassis Welding will Encounter the Problems and Solutions

Large chassis welding will encounter the following problems: poor weld quality, defects, porosity, cracks and other problems may appear; material deformation by high temperature; material discoloration by high temperature, affecting the aesthetics; welding may produce welding slag or spatter, affecting the quality of welding. Dongguan Jiatong Precision Hardware Products Co., Ltd. has professional solutions to […]

-

Sheet Metal Operator Shell Processing

Sheet metal operating table shell processing is one kind of sheet metal processing, which is the processing of metal plates into certain shapes through stamping, bending and shearing to meet the needs of customers. With the continuous development of science and technology and the increase of people’s demand for personalized products, sheet metal operating table […]

-

Application of Aluminum Alloy Profiles on TVs

First, the use of aluminum profiles in decorative parts: As the middle frame of super-narrow, bezel-less TVs is bent with aluminum profile, if the decorative parts use the same metal material, it can avoid problems such as large assembly gaps brought by injection molding decorative parts, so the material of the lower frame of TVs […]

-

What is the Finishing Process?

Currently, there is an increasing demand for sheet metal cabinets in various industries, mainly because they can play a good role in protecting electronic components. In order to ensure the quality of sheet metal cabinets in production, there is often some processing work to be done after forming. So do you know what processing needs […]

-

How to Choose the Right Material for the CNC Machined Parts?

1、Whether the rigidity of the material is sufficient Rigidity is the primary consideration when choosing materials, because the product needs a certain stability and wear resistance in the actual work, the rigidity of the material determines the feasibility of product design. According to the characteristics of the industry, non-standard tooling design, usually choose 45 steel […]

-

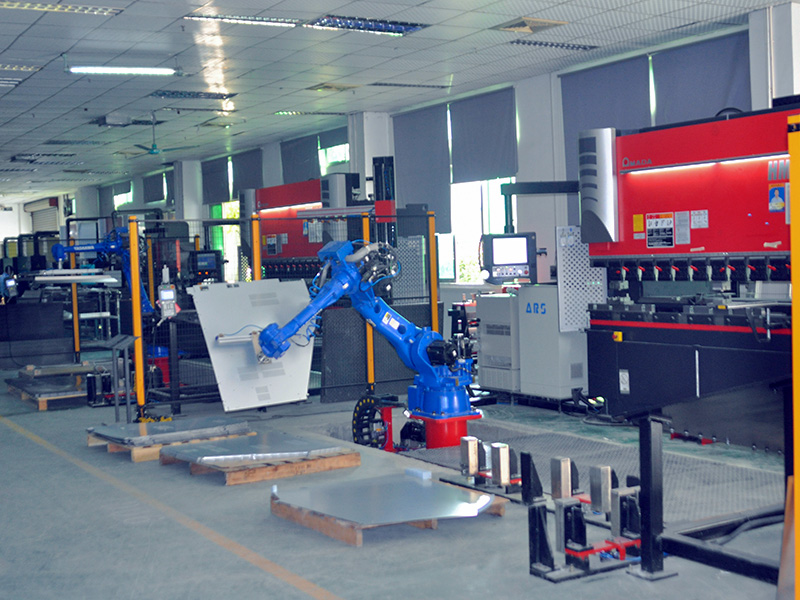

Three Intelligent Technologies for Sheet Metal Processing

The sheet metal processing industry has been in full swing in recent years, and its processing technology has been widely used in various industries, and with the renewal of technology, intelligent new technology is widely promoted and used, the following are three intelligent processing technologies. 1, CNC machining CNC machining technology is the use of […]

-

What Types of Patterned Aluminum Sheet ?

Patterned aluminum sheet is a high-cost modern material with many types, which is very widely used in furniture, such as refrigerators, air conditioners, carriages, platforms, screen skeletons, various suspension beams, etc. According to the aluminum plate pattern can be divided into the following types. Five bars aluminum alloy pattern plate because the pattern on the […]

-

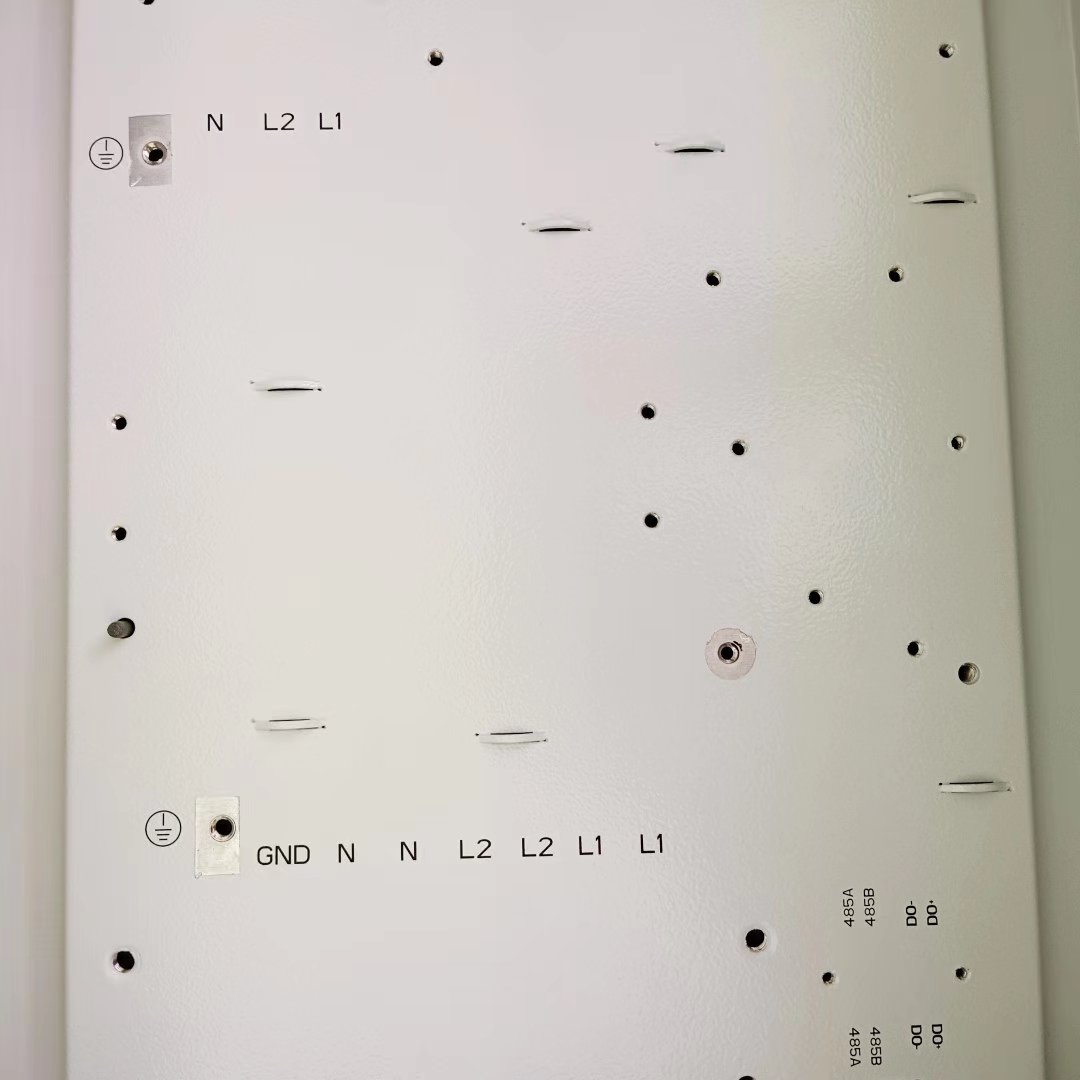

How to Design a Custom Sheet Metal Cabinet?

Designing a custom sheet metal cabinet involves several steps. Below are the general requirements for the design process. Determine the purpose of the cabinet, including the type of items that will be stored in it, the environment it will be used in, and any special features or requirements.Determine the dimensions: Determine the overall size of […]

-

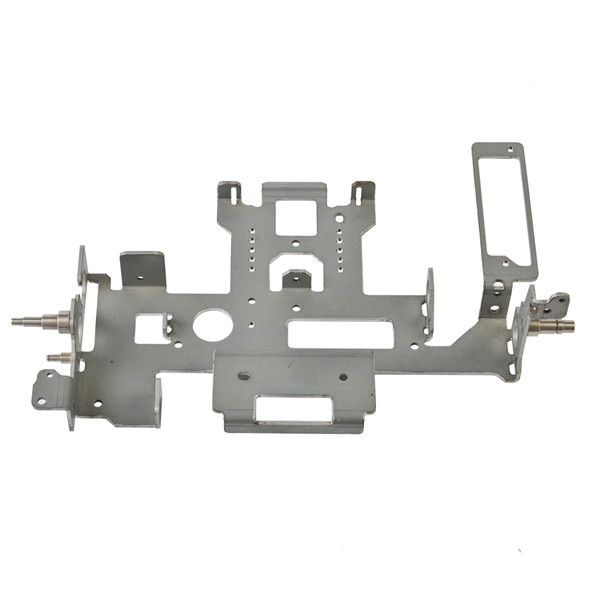

Sheet Metal Manufacture and Quality Control

Sheet metal parts are important components of injection molding machines, not only for their complex structure but also for their beautiful appearance and safety protection. The main processes are: cutting, shearing, punching, folding, welding, splicing, molding, spraying, etc. It is the last process of injection molding machine assembly. Due to the complicated process, the outsourcing […]