Category: Technology News

-

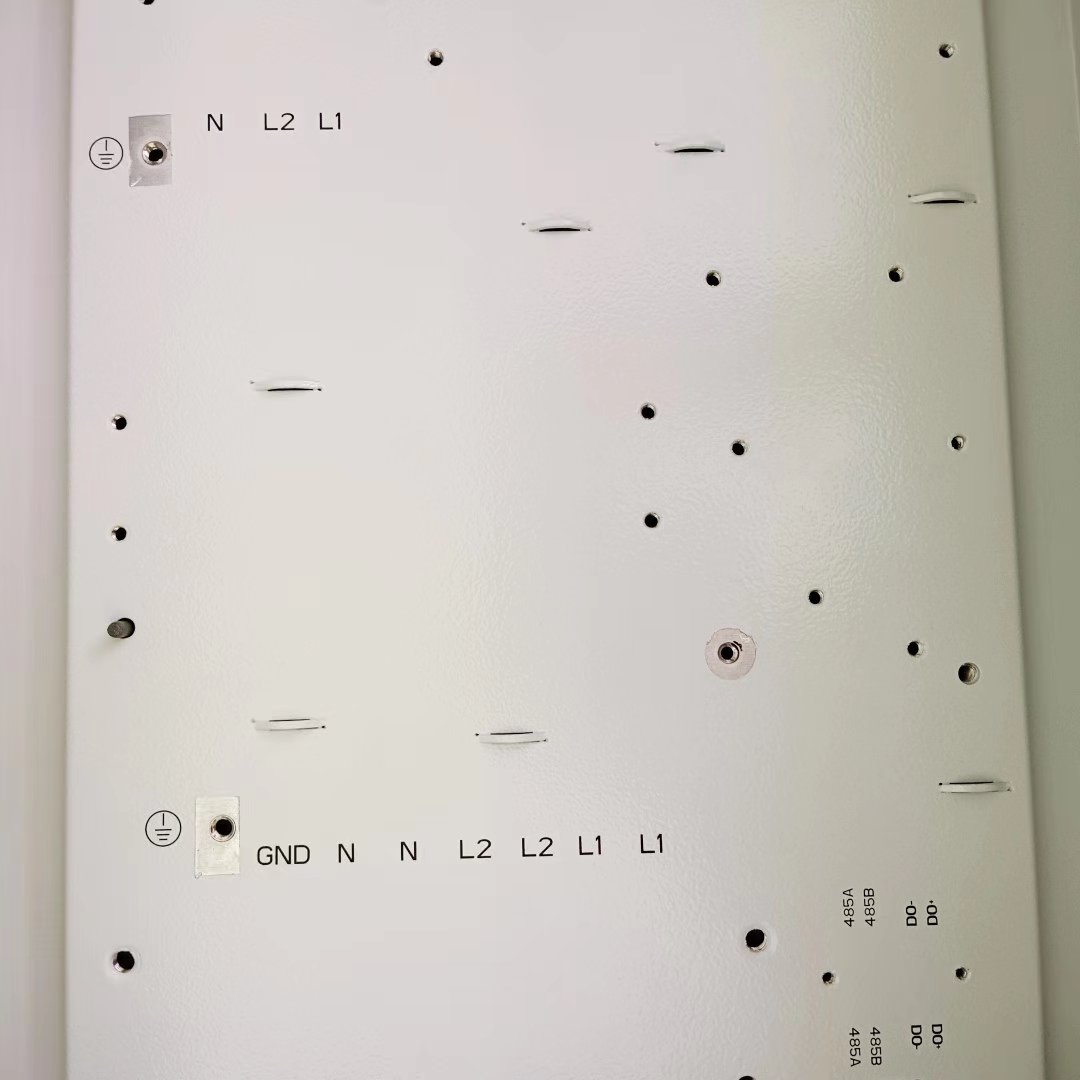

What is the Finishing Process?

Currently, there is an increasing demand for sheet metal cabinets in various industries, mainly because they can play a good role in protecting electronic components. In order to ensure the quality of sheet metal cabinets in production, there is often some processing work to be done after forming. So do you know what processing needs […]

-

What is the Difference Between Plasma Cutting and Laser Cutting?

Laser cutting, which originated in the mid-1960s, is a cutting process characterized by the use of an amplified laser as the “tool” and a computer numerical control program to perform the cutting operation. The main lasers used in laser cutting are CO2, neodymium (Nd), yttrium aluminum garnet (Nd: YAG) and fiber optic lasers, all of […]

-

How to Choose the Right Material for the CNC Machined Parts?

1、Whether the rigidity of the material is sufficient Rigidity is the primary consideration when choosing materials, because the product needs a certain stability and wear resistance in the actual work, the rigidity of the material determines the feasibility of product design. According to the characteristics of the industry, non-standard tooling design, usually choose 45 steel […]

-

Three Intelligent Technologies for Sheet Metal Processing

The sheet metal processing industry has been in full swing in recent years, and its processing technology has been widely used in various industries, and with the renewal of technology, intelligent new technology is widely promoted and used, the following are three intelligent processing technologies. 1, CNC machining CNC machining technology is the use of […]

-

Aluminum Sheets in Three Major Fields

Aluminum sheets are rectangular sheets made from rolled aluminum ingots and are classified as pure aluminum sheets, alloy aluminum sheets, thin aluminum sheets, medium-thick aluminum sheets and patterned aluminum sheets. Aluminum consumption through the gradual promotion of changes, technology maturity, policy guidance and support, the current expansion of applications include: transportation, building construction, power sector. […]

-

What Types of Patterned Aluminum Sheet ?

Patterned aluminum sheet is a high-cost modern material with many types, which is very widely used in furniture, such as refrigerators, air conditioners, carriages, platforms, screen skeletons, various suspension beams, etc. According to the aluminum plate pattern can be divided into the following types. Five bars aluminum alloy pattern plate because the pattern on the […]

-

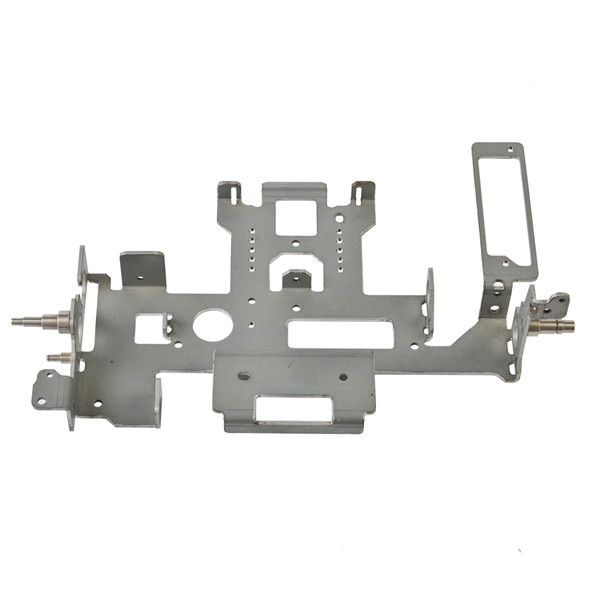

What are the Process used in Sheet Metal?

Sheet metal fabrication, which is also known as metalworking, is more about transforming metal sheets so that they can be used in many different ways. There are many ways of processing, such as stamping, cutting and trimming to change the properties and shape of the metal. The use of this processing technology can bring a […]

-

What is Welding Robot used for?

The welding robot can process complex and precise metal workpieces, and the welded workpieces are flat without grinding, polishing or only simple treatment, and no filler material is needed for welding, saving production costs. It can easily carry large workpieces and process them even in narrow working spaces. It has good welding quality, high efficiency, […]

-

What is the Advantage of Aluminum Box Compared with Iron Box?

Aluminum boxes can be divided into ordinary boxes and easy-to-open cans, easy-to-open cans used for beer and beverages believe that we are very much in contact with, the amount is also very large, the global annual calculation of more than 10 billion easy-to-open cans. Aluminum boxes are used as ordinary boxes and are becoming popular […]

-

What is the Sheet Metal Welding Process like?

Sheet metal welding has argon arc welding, spot welding, carbon dioxide shielded welding, manual arc welding, etc. Spot welding should first consider the location of the sheet metal workpiece to be welded, and consider doing positioning tooling to ensure the spot welding position is accurate when mass production. In order to weld firmly, hitting the […]