Tag: sheet metal supplier

-

How to Find the Right Metal Supplier for Your Next Project

Finding the right sheet metal supplier quickly can be a daunting task, but there are some steps that you can take to make sure you find the best one. First and foremost, it is important to make sure the supplier has quality parts [1]. You can easily find out about the quality of parts by […]

-

Sheet Metal Design Basics

With the widespread use of sheet metal, sheet metal design has become a very important part of the product development process. What should I pay attention to in sheet metal design? Sheet metal design generally has the following design points. (1) Sheet metal design should first pay attention to the relationship between the sheet metal […]

-

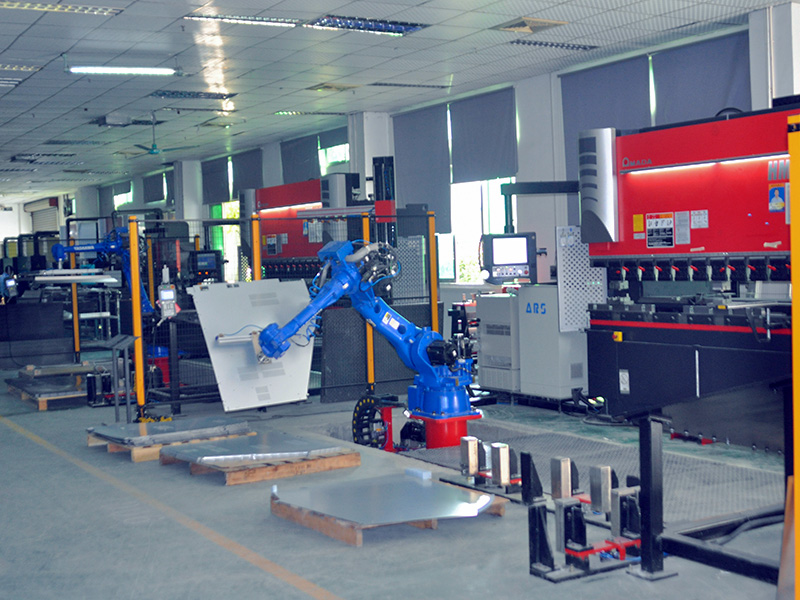

Sheet Metal Manufacture and Quality Control

Sheet metal parts are important components of injection molding machines, not only for their complex structure but also for their beautiful appearance and safety protection. The main processes are: cutting, shearing, punching, folding, welding, splicing, molding, spraying, etc. It is the last process of injection molding machine assembly. Due to the complicated process, the outsourcing […]

-

How to Determine the Bending Radius of Sheet Metal? What is the Relationship with the Plate Thickness?

The bending radius of a sheet is a value required in the sheet drawing and it is difficult to determine its size in the actual process. In fact, the bending radius of sheet metal is related to the thickness of the material, the pressure of the bending machine and the width of the lower die […]

-

Sheet Metal Structure Design Principles

The manufacturability of sheet metal parts refers to the difficulty of parts in punching, bending and stretching. Good technology should ensure less material consumption, less number of processes, simple die structure, high service life and stable product quality. In general, the biggest impact on the manufacturability of sheet metal parts is the performance of materials, the geometry, size and accuracy requirements […]

-

Sheet metal PC chassis

Steel plate: steel plates must be thick. Shop around. You can feel what is thick and what is thin by tapping with your fingers. Painting: for a qualified cabinet, all steel needs painting, and the painting must be average, so that it can be well rustproof and dustproof. Structure layout: Generally speaking, there are many […]

-

Principles of design and installation of metal cabinet

1、 In the principle of convenient installation, the hanging beam is adopted, which is convenient and flexible for installation and movement. 2、 The principle of internal shielding is to adopt high-density mesh front and rear to ensure the shielding inside the cabinet. 3、 Considering the load-bearing factors, the reinforced fixed tray is attached with reinforcing […]

-

Customized processed sheet metal parts

Materials commonly used in sheet metal processing include cold rolled sheet (SPCC), hot rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (Cu) brass, red copper, beryllium copper, aluminum sheet (6061, 5052, 1010, 1060, 6063, hard aluminum, etc.), stainless steel (mirror, wire drawing surface, fog surface), 1. Cold rolled sheet SPCC, mainly used for electroplating and […]

-

Installation of aluminum sheet metal parts

Aluminum profile + sheet metal parts are a good combination, which can be used on the hood, chassis, protective cover, etc., to prevent dust, noise, protect personal safety and so on. Moreover, there are many colors of sheet metal parts, such as yellow, blue, red, etc. when used on mechanical equipment, they are more conspicuous […]

-

Stainless steel sheet metal cabinet

All conductive parts are made of copper busbar series or pure copper plate according to gb5585-85 rules, and the surface plating is made according to the requirements of the drawing. If bending is required, annealing treatment shall be carried out before bending, and the bending fillet radius shall be greater than the thickness of the […]