Author: Jiatong

-

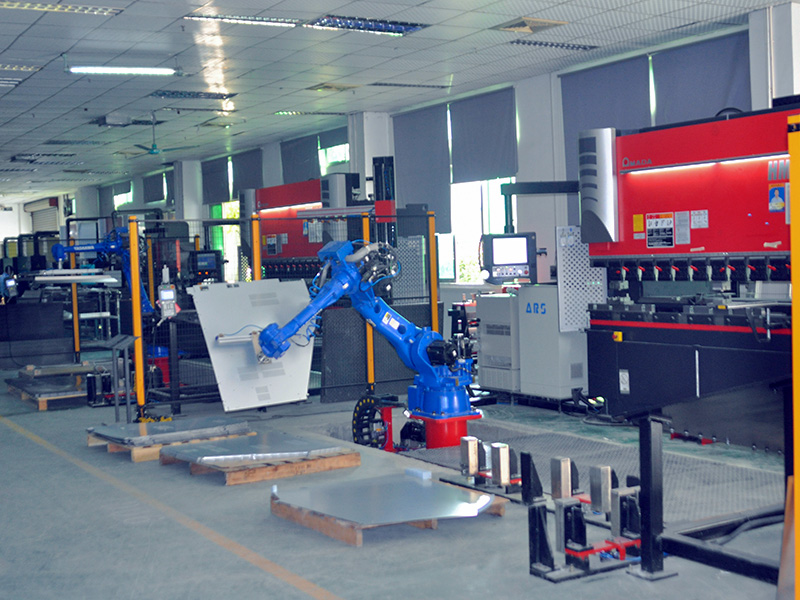

How is the car shell stamped out?

In the field of car body manufacturing, it includes four major processes: stamping, welding, painting and final assembly. However, the equipment required by China for these processes has completely relied on imports for a long period of time, so the cost of automobile manufacturing has remained high. In order to reduce costs, our company began […]

-

What is the role of the bending machine in the processing of automotive sheet metal parts?

CurrentlyAutomotive sheet metal partsThere are many types of bending machines, which can be divided into mechanical (servo motor) and hydraulic type according to the rotation mode. According to the control system, it can be divided into simple manual bending machine, ordinary domestic digital positioning bending machine, process control digital full-function bending machine. According to the […]

-

How many ways are there to clean auto parts?

Due to people’s insufficient understanding of the role of parts cleaning, the parts cannot be thoroughly cleaned, which affects the assembly quality. As a result, failures occur frequently after the completion of the construction, the parts are worn out, the service life is reduced, and even traffic accidents are caused. Therefore, parts cleaning should arouse […]

-

What are the common processing methods for automotive sheet metal parts?

The process of using various equipment to change the shape of sheet metal is called sheet metal processing, and the main processes are sheet metal shearing, bending forming, welding, riveting, etc.It can also be processed by stamping, bending, stretching, etc.car parts, We can use it to carry out a series of treatments on metal. Common […]