Category: Technology News

-

Installation requirements for sheet metal distribution box

The installation requirements of the distribution box are: the distribution box shall be made of non-combustible materials; Open distribution boards can be installed in production sites and offices with low risk of electric shock; Closed cabinets shall be installed in processing workshops, casting, forging, heat treatment, boiler rooms, carpentry rooms and other places with high […]

-

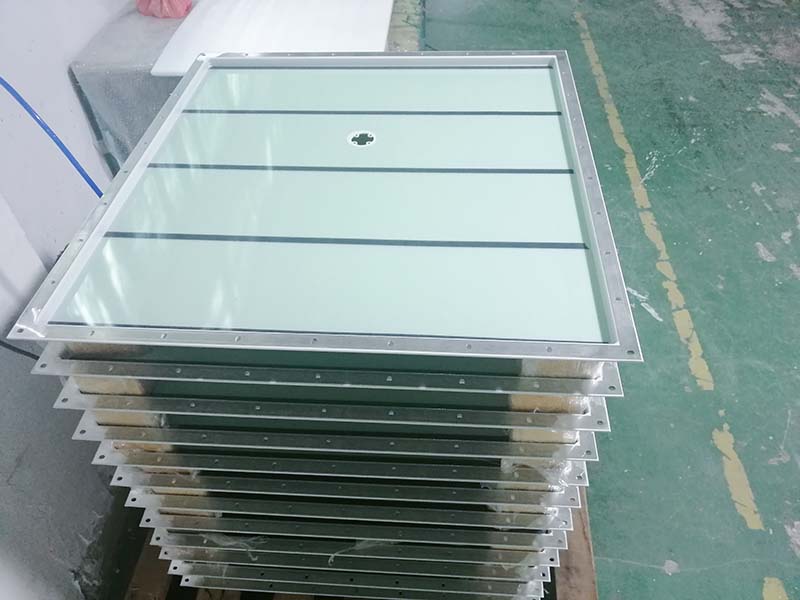

Sheet metal parts, sheet metal accessories

Sheet metal is a comprehensive cold working process for sheet metal (usually less than 6mm), including shearing, punching / cutting / compounding, folding, welding, riveting, splicing, forming (such as automobile body), etc. Its remarkable feature is that the thickness of the same part is the same. The products processed by the sheet metal process are […]

-

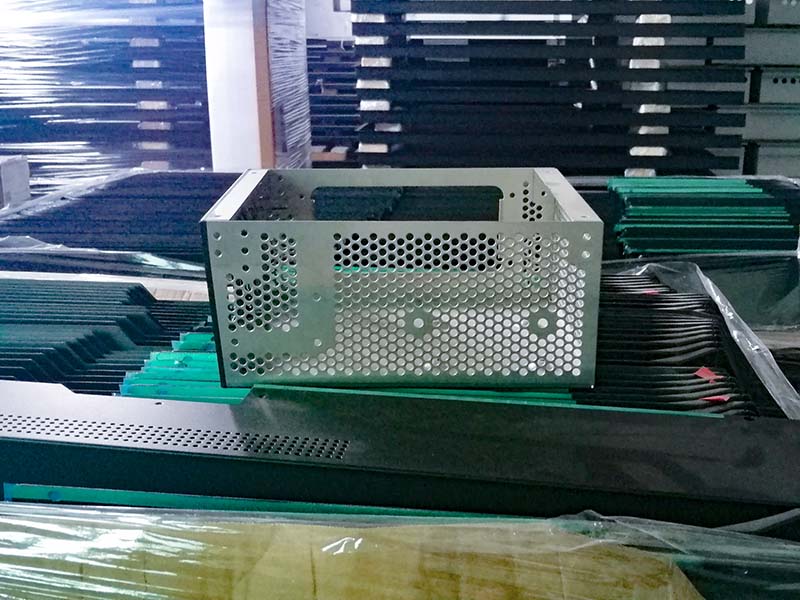

Machine equipment sheet metal shell

The machine equipment sheet metal shell is a reasonable use of the sheet metal shell. The body is an integrated overall structure. The surface shell is treated by special sheet metal process, smooth and bright, anti-collision, anti-oxidation, solid and durable, easy to clean and maintain. The overall design is ergonomic, safe and simple to operate, […]

-

L-shaped bracket

L-shaped bracket is one of the most common bracket types. As the name suggests, it has an L-shaped profile after bending along the uniaxial direction, usually forming a 90 ° angle. L-brackets are used in many applications where horizontal objects need to be mounted to vertical objects. L brackets are usually designed at 90 ° […]

-

Overview of pressure connection technology

The principle of the pressure connection method is to use punch, female die and various stamping equipment to extrude various material components, so that the materials of different sizes and compositions are slowly deformed, and finally connected into a whole. It is a method to realize the connection through internal fitting. It is a modern […]

-

Composition of stamping die

The composition of stamping dies will depend on the type, composition and difference of dies, and there are two categories: forward configuration structure and reverse configuration structure. The former is the most commonly used structure, and the latter structure is mainly used for drawing forming dies or matching special dies. The main work includes: (1) […]

-

Sheet metal deburring machine has the advantage of huge processing quantity

The more parts you need to process, the greater the value of using a deburring machine. In mass processing, it is particularly important to consider saving time and cost. These two factors play a crucial role in the company’s profitability. According to experience, the working efficiency of a worker operating a modern sheet metal deburring […]

-

Advantages of CNC stamping

(1) Because of the convenience and rapidity of NC machining, it can greatly shorten the manufacturing time of molds, improve the working quality of molds, and provide help for manufacturers to reduce the processing cost of molds. This will help the machinery manufacturing industry to obtain new development space under the competitive pressure at this […]

-

Three stamping models

Continuous mode The continuous die is a die with two or more working positions. The material is sent to one working position step by step with the stroke of the press, so that the stamping part can be formed step by step. Single process mold Single process die is a die that only completes one […]

-

Stamping blanks and tools

The blanks for stamping are mainly hot-rolled and cold-rolled steel plates and strips. 60 ~ 70% of the world’s steel products are plates, most of which are made into finished products by stamping. Automobile body, chassis, oil tank, radiator, boiler drum, container shell, iron core silicon steel sheet of motor and electrical appliance are all […]