Category: MFG Guide

-

How to Determine the Bending Radius of Sheet Metal? What is the Relationship with the Plate Thickness?

The bending radius of a sheet is a value required in the sheet drawing and it is difficult to determine its size in the actual process. In fact, the bending radius of sheet metal is related to the thickness of the material, the pressure of the bending machine and the width of the lower die […]

-

Sheet Metal Structure Design Principles

The manufacturability of sheet metal parts refers to the difficulty of parts in punching, bending and stretching. Good technology should ensure less material consumption, less number of processes, simple die structure, high service life and stable product quality. In general, the biggest impact on the manufacturability of sheet metal parts is the performance of materials, the geometry, size and accuracy requirements […]

-

Scratch on the surface of metal chassis

1.The factors causing the scratch on the processing surface of sheet metal chassis are relatively complex and revolve around the whole process of commodity manufacturing, but they can be generally divided into two categories: one is the scratch of commodities during production, and the other is the scratch caused by freight logistics in the production […]

-

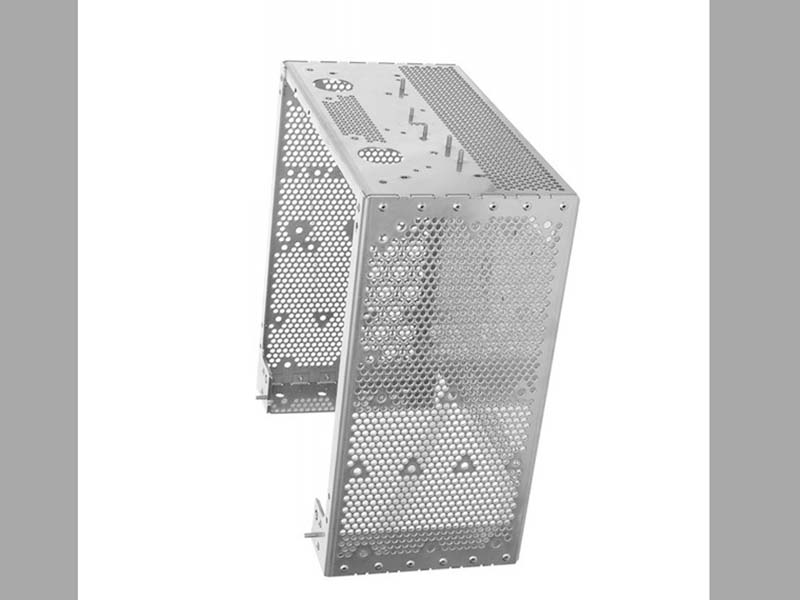

Sheet metal operation enclosure

The working casing is generally used in the environment with poor conditions. There are many places such as noise and dust in sheet metal processing plants. The part of the machine board is divided into two parts, which are represented in the form of a basic CPU card. Foreword: the working machine is generally used […]

-

Sheet metal outdoor cabinet

Outdoor cabinet refers to the cabinet made of metal or non-metal materials under the direct influence of natural climate, which does not allow unauthorized operators to enter and operate, and provides outdoor physical working environment and safety system for wireless communication stations or wired network station workstations. Cabinet suitable for outdoor environment, such as roadside, […]

-

How to classify laser cutting machine according to cutting workpiece?

It is relatively simple to distinguish from the cutting materials, as follows: A metal laser cutting machine. The power of laser is generally large, ranging from 500 watts to 3000 watts or higher. It is used for cutting carbon steel, stainless steel, copper, aluminum, alloy steel and other metal materials. B non-metallic laser cutting machine. […]

-

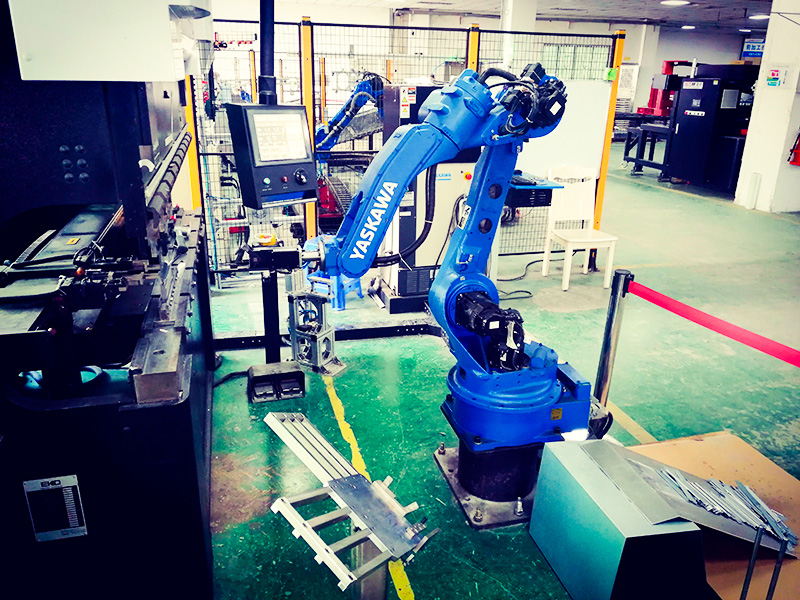

Do you have to use the die for sheet metal bending?

Different sheet metal processing parts enter the corresponding process according to the processing requirements. There are bending, riveting, flanging, tapping, spot welding, convex hull and segment difference. Sometimes after bending one or two times, the nut or stud shall be pressed well. The parts with mold convex hull and segment difference shall be processed first, […]

-

Fiber laser cutting machine vs CO2 laser cutting machine

1.Excellent beam quality: smaller focus spot, finer cutting lines, higher work efficiency and better processing quality; Its cutting speed is 2 times as high as that of CO2 cutting machine; Extremely high stability: the world’s top imported fiber laser is adopted, with stable performance, and the service life of key components can reach […]

-

Brief introduction of embossing process and coining process

Embossing and embossing processes are widely used in sheet metal parts, including label pasting position indication, product code, production date, version, manufacturer code, and even pattern. These two processes can be used for processing. Metal Parts Manufacturing | Prototype Sheet Metal | 4×4 Corner Brackets ①Embossing process Embossing is to change the thickness of the material, fill […]

-

Some measures to improve the quality of sheet metal parts

(1) Eliminate various factors that may affect the quality of sheet metal. In the process of sheet metal processing, generally speaking, the factors that will affect the quality of sheet metal processing include the following aspects: Physical and mechanical properties: mainly the metallographic arrangement change of the appearance material and the appearance residual stress. Generally […]