Category: MFG Guide

-

Advantages and disadvantages of sheet metal processing stamping parts

advantage low cost Sheet metal stamping is a low-cost manufacturing technology. Its cost is usually lower than other methods, making it an ideal choice for small businesses with limited budgets. Since this method does not require molds or tools to create assemblies or parts, many people believe that it is also low cost. However, the […]

-

How to improve the machining accuracy of sheet metal machining?

Whether it is a sheet metal processing manufacturer or an individual, the sheet metal processing accuracy may be unsatisfactory. Therefore, in order to better ensure the power, reduce material waste and reduce labor, we need to improve the machining accuracy of sheet metal machining. Do you know how to improve the machining accuracy of sheet […]

-

Common problems of sheet metal processing stamping parts

The sheet metal stamping process converts hot-rolled or cold-rolled steel plates into the shape needed to make your parts. This technology allows a large number of parts to be produced at the same time, but it can also cause about 15% of raw materials to become waste. The equipment used in this method requires less […]

-

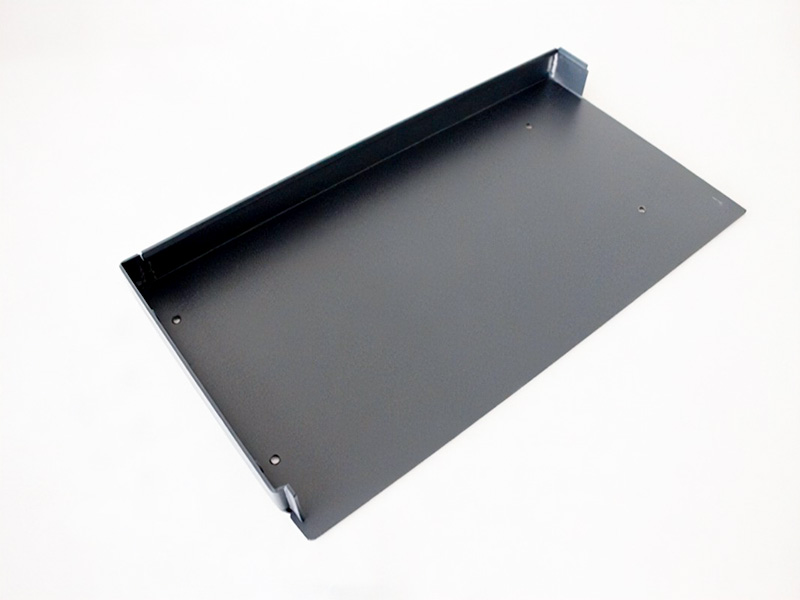

Methods to prevent corrosion of sheet metal shell

In the production of sheet metal shell, sometimes no matter what material we use, the sheet metal shell may be corroded after long-term use due to the problem of wet weather. When this phenomenon occurs, it will undoubtedly cause great inconvenience to us. In order to effectively solve this problem, we can greatly reduce the […]

-

Characteristics and advantages of sheet metal design

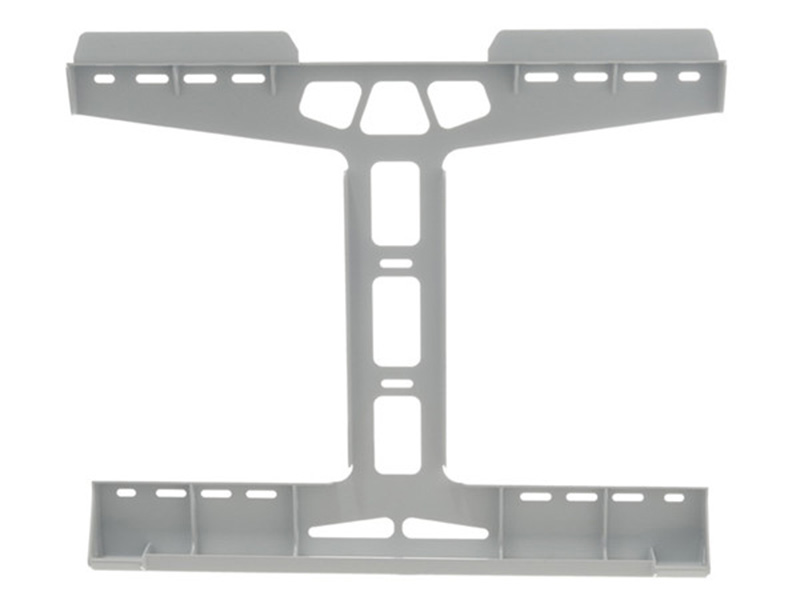

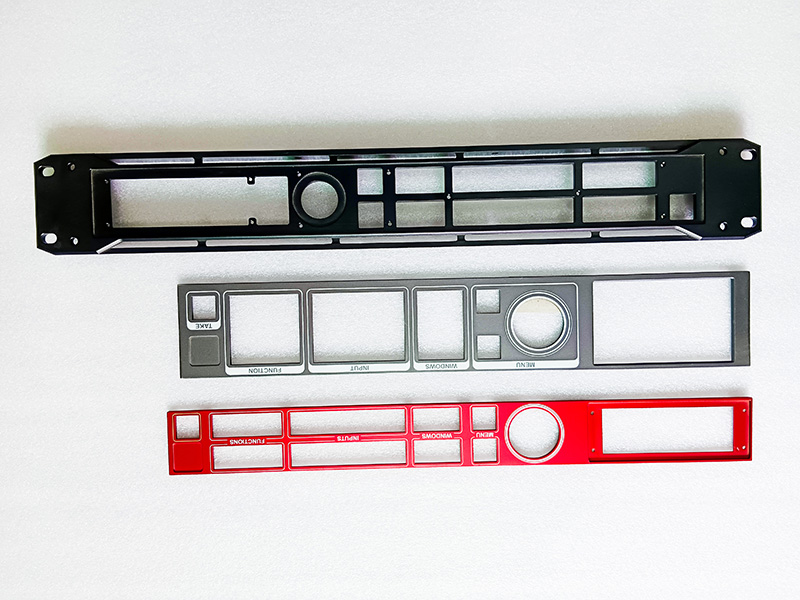

First of all, we need to know what is sheet metal? The remarkable feature of sheet metal is that the thickness of the same part is the same. According to the definition, sheet metal is a cold working process of sheet metal, including shearing, punching / cutting / compounding, folding, riveting, splicing, forming (such as […]

-

Characteristics of sheet metal manufacturing industry

Because most sheet metal manufacturing is the production and manufacturing of cold or hot separation and forming of raw materials without changing the cross-sectional characteristics of sheet metal materials, aluminum profiles and pipe fittings. Moreover, the produced metal material causes plastic deformation below the manufacturing hardening temperature, so it does not cause cutting. It can […]

-

Development and application of sheet metal manufacturing industry

Sheet metal manufacturing is the blanking or cold and hot forming of sheet metal materials, aluminum profiles and pipe fittings without changing their cross-sectional characteristics. Then the assembly is carried out by means of electric welding, riveting and screw connection, and the production and manufacturing mode of the specified metal structure is produced. The key […]

-

Causes of burr production

Causes of burr production in hardware stamping parts(Sheet metal parts) 1.The first possible reason is that the knife edge is blunt. Burr will be produced when the cutting edge is worn, blunt or gnawed. The factors affecting the blunt edge are: 1)It is not lubricated in time during operation, resulting in rapid wear; 2)Didn’t grind […]

-

Sand blasting

Sand blasting is widely used on metal surfaces The purpose is to overcome and cover up some defects of aluminum alloy in the machining process and meet some special requirements of customers for product appearance.The principle is only to impact the accelerated abrasive particles on the metal surface to remove embroidery, deburring, oxide layer or […]

-

Introduction to Surface Treatment Technology

Introduction to Surface Treatment Technology 1)What is surface treatment? Surface treatment: change the shape, chemical composition and organizational structure of the product surface and near surface area by the most economical and effective method, effectively improve and improve the decorative performance, corrosion resistance and wear resistance of the product, and prolong the service life of […]