Tag: sheet metal fabrication

-

What factors affect the quality of sheet metal chassis?

Generally speaking, the basic equipment of sheet metal processing factory includes plate shears, CNC punches, laser plasma, water jet cutting machines, compound machines, bending machines and various auxiliary equipment, such as uncoilers, leveling machines, deburring machines, spot welding machines, etc. Metal plate processing is called sheet metal processing. Specifically, for example, using plates to manufacture […]

-

Aluminum sheet metal chassis

The density of aluminum is very small, only 2.7 grams / cubic centimeter. The specific heat capacity of aluminum is 0.88*1000 j/ (kg* ℃), and the density of steel is 7.9 g / cubic centimeter. The specific heat capacity is about 0.46*1000j/ (kg* ℃) in terms of density, steel is nearly three times that of […]

-

Scratch on the surface of metal chassis

1.The factors causing the scratch on the processing surface of sheet metal chassis are relatively complex and revolve around the whole process of commodity manufacturing, but they can be generally divided into two categories: one is the scratch of commodities during production, and the other is the scratch caused by freight logistics in the production […]

-

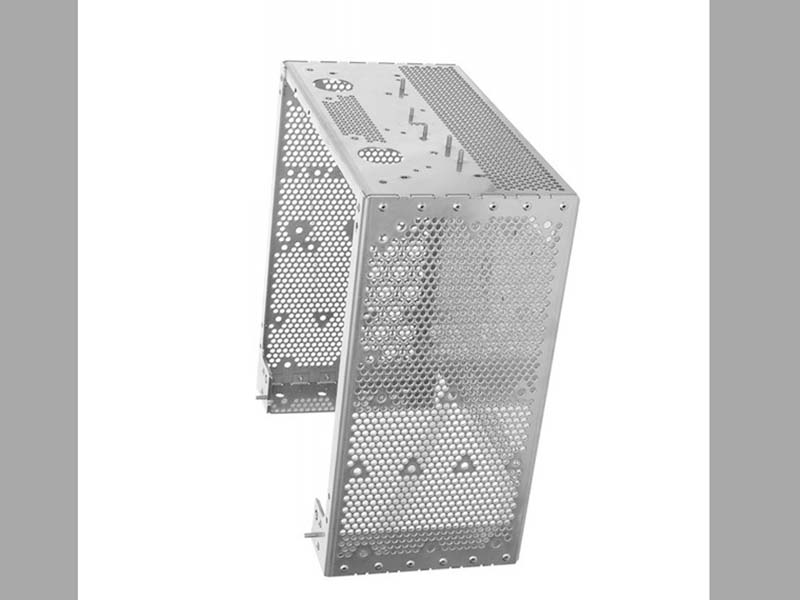

Sheet metal operation enclosure

The working casing is generally used in the environment with poor conditions. There are many places such as noise and dust in sheet metal processing plants. The part of the machine board is divided into two parts, which are represented in the form of a basic CPU card. Foreword: the working machine is generally used […]

-

Sheet metal network cabinet

Network cabinet is a rectangular cabinet composed of frame and cover plate. It can install switches, optical fiber adapters, optical fiber distribution frames and other equipment in one cabinet. It has the properties of electromagnetic isolation, noise isolation, ventilation and heat dissipation, anti-vibration, anti-corrosion and so on, and can ensure the stable and reliable work […]

-

Which is better, metal shell or plastic shell of electronic products?

The shell metal of electronic products is better. Relatively speaking, the metal shell is resistant to falling and more durable. The stainless steel shell has the advantages of dirt resistance, strong metal texture, good sealing, better sound quality, strong plasticity, oxidation resistance, low processing difficulty, short construction period, cost saving, etc; Plastic is not resistant […]

-

Steel battery bracket

In the early days, square batteries were mostly steel shells, which were mostly used for mobile phone batteries. Later, due to the low weight specific energy of steel shells and poor safety, they were gradually replaced by aluminum shells and soft packed lithium-ion batteries. However, in the column battery, there is another scene. The vast […]

-

Manufacturing industry will complete the digital transformation

In the near future, the manufacturing industry will complete the digital transformation and finally realize the so-called intelligent manufacturing. More and more factory managers believe that investment in emerging technologies can achieve better development in the next few years. With the continuous invasion of new technologies, the manufacturing industry will experience all previous and future […]

-

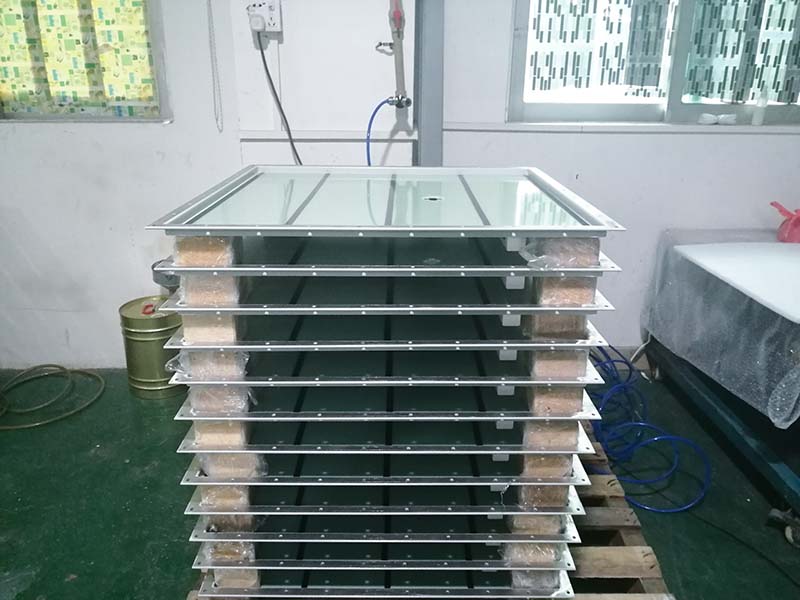

Simple sheet metal cabinet

Talk about your impression of the sheet metal cabinet. Is it unsmooth, heavy, rustic, or simple, airy, and beautiful? But which design style and type of sheet metal cabinet do you prefer? In the design scheme of sheet metal cabinet, in addition to meeting the needs of equipment versatility, it is also necessary to pay […]

-

Waterproof design of sheet metal structure cabinet

In the design of the cabinet with sheet metal structure, the key parts requiring waterproof design are mainly the parts where the various structural parts of the cabinet are connected, as well as the door panels, locks, hinges and other parts of the cabinet. For the waterproof design of these parts, the following different design […]