Tag: sheet metal machining

-

Process using sheet metal ERP

Curling Edge wrapping is a sheet metal forming process. After initial production, sheet metal usually has sharp edges with “burrs”. The purpose of curling is to make sharp and rough sheet metal edges smooth to meet the needs of the project. bend Bending is another common sheet metal forming process. Manufacturers usually use the brake […]

-

The best device for handling metal dust

The primary task of cleaning the deburring machine is to absorb the residual grinding dust, so it is very important to configure a set of high-power dust removal system. But sometimes, despite the well-designed, it is inevitable that dust will accumulate in some dead corners of the machine. Therefore, the user should ensure that the […]

-

How to classify laser cutting machine according to cutting workpiece?

It is relatively simple to distinguish from the cutting materials, as follows: A metal laser cutting machine. The power of laser is generally large, ranging from 500 watts to 3000 watts or higher. It is used for cutting carbon steel, stainless steel, copper, aluminum, alloy steel and other metal materials. B non-metallic laser cutting machine. […]

-

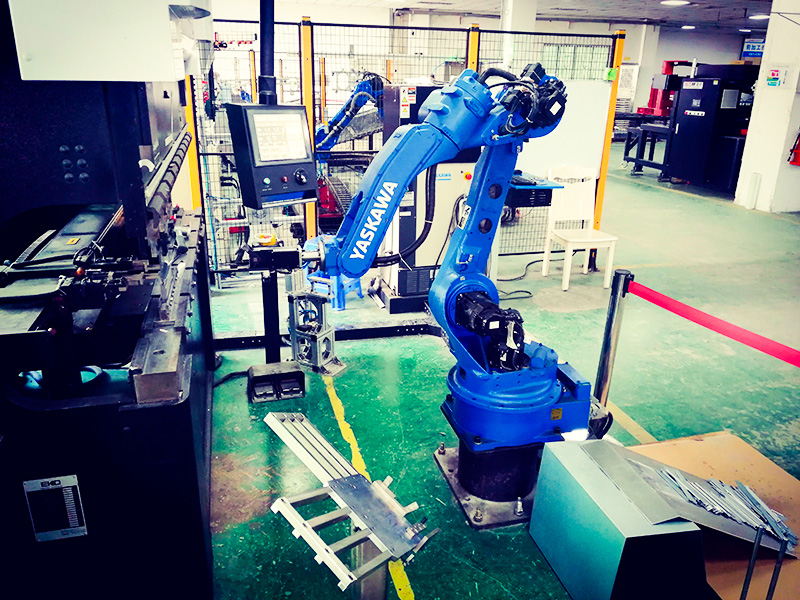

Sheet metal and household appliances

With the innovation of household appliances, the types of household appliances have shown diversified development. In order to meet the personalized needs of users, the household appliance manufacturing industry is constantly reforming and innovating both in technology and appearance design. As the main component of electrical appliances, sheet metal parts processed with sheet metal materials […]

-

Do you have to use the die for sheet metal bending?

Different sheet metal processing parts enter the corresponding process according to the processing requirements. There are bending, riveting, flanging, tapping, spot welding, convex hull and segment difference. Sometimes after bending one or two times, the nut or stud shall be pressed well. The parts with mold convex hull and segment difference shall be processed first, […]

-

Fiber laser cutting machine vs CO2 laser cutting machine

1.Excellent beam quality: smaller focus spot, finer cutting lines, higher work efficiency and better processing quality; Its cutting speed is 2 times as high as that of CO2 cutting machine; Extremely high stability: the world’s top imported fiber laser is adopted, with stable performance, and the service life of key components can reach […]

-

Improve the technical level of sheet metal structure design

On the premise of ensuring the strength, the structural design of sheet metal parts should also ensure the beauty and process feasibility of sheet metal parts. The processing technology and materials with convenient processing and low cost must be selected, and the utilization rate of materials must be ensured. The thickness of plates with the […]

-

Brief introduction of embossing process and coining process

Embossing and embossing processes are widely used in sheet metal parts, including label pasting position indication, product code, production date, version, manufacturer code, and even pattern. These two processes can be used for processing. Metal Parts Manufacturing | Prototype Sheet Metal | 4×4 Corner Brackets ①Embossing process Embossing is to change the thickness of the material, fill […]

-

Some measures to improve the quality of sheet metal parts

(1) Eliminate various factors that may affect the quality of sheet metal. In the process of sheet metal processing, generally speaking, the factors that will affect the quality of sheet metal processing include the following aspects: Physical and mechanical properties: mainly the metallographic arrangement change of the appearance material and the appearance residual stress. Generally […]

-

How to understand sheet metal processing drawings?

In sheet metal processing, understanding sheet metal drawings is one of the basic skills that every technician must have. Whether making drawings in the early stage or processing drawings in the later stage is one of the important factors affecting the post-processing of sheet metal parts. First of all, we should grasp the principle of […]