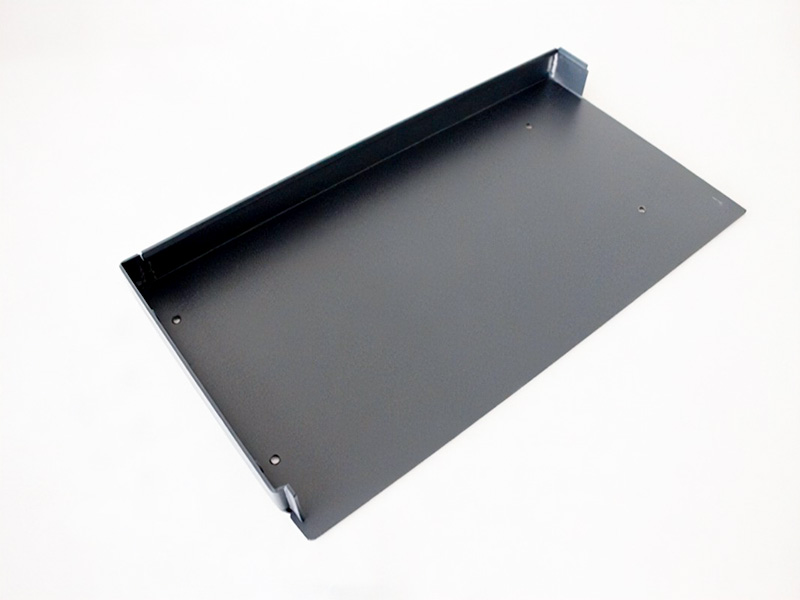

Tag: sheet metal cover

-

Sheet metal PC chassis

Steel plate: steel plates must be thick. Shop around. You can feel what is thick and what is thin by tapping with your fingers. Painting: for a qualified cabinet, all steel needs painting, and the painting must be average, so that it can be well rustproof and dustproof. Structure layout: Generally speaking, there are many […]

-

Principles of design and installation of metal cabinet

1、 In the principle of convenient installation, the hanging beam is adopted, which is convenient and flexible for installation and movement. 2、 The principle of internal shielding is to adopt high-density mesh front and rear to ensure the shielding inside the cabinet. 3、 Considering the load-bearing factors, the reinforced fixed tray is attached with reinforcing […]

-

Customized processed sheet metal parts

Materials commonly used in sheet metal processing include cold rolled sheet (SPCC), hot rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (Cu) brass, red copper, beryllium copper, aluminum sheet (6061, 5052, 1010, 1060, 6063, hard aluminum, etc.), stainless steel (mirror, wire drawing surface, fog surface), 1. Cold rolled sheet SPCC, mainly used for electroplating and […]

-

Installation of aluminum sheet metal parts

Aluminum profile + sheet metal parts are a good combination, which can be used on the hood, chassis, protective cover, etc., to prevent dust, noise, protect personal safety and so on. Moreover, there are many colors of sheet metal parts, such as yellow, blue, red, etc. when used on mechanical equipment, they are more conspicuous […]

-

Stainless steel sheet metal cabinet

All conductive parts are made of copper busbar series or pure copper plate according to gb5585-85 rules, and the surface plating is made according to the requirements of the drawing. If bending is required, annealing treatment shall be carried out before bending, and the bending fillet radius shall be greater than the thickness of the […]

-

What details should be paid attention to in the processing of sheet metal cabinet?

At present, in the processing industry, sheet metal cabinet processing is one of the more prominent processing forms, because the sheet metal cabinet products with good strength and long service life can well protect the sheet metal cabinet equipment, so as to prevent any damage to the inner parts. However, in order to better ensure […]

-

A summary of some bending elements

Bending is a stamping process that uses pressure to force the material to produce plastic deformation, so as to form a certain angle and curvature shape. Common bending includes V-shaped bending, Z-shaped bending and reverse bending. The following is a summary of some bending elements : Bending height The bending height shall be at least […]

-

Quality and specification of grinding

1) Grinding and polishing quality After grinding, the surface of the parts shall be free of unevenness, burr, concave hole and trachoma. After polishing, the overall surface shall be smooth. The surface of stainless steel products or welding parts(custom sheet metal parts) shall be treated with XX mesh wire drawing. After wire drawing, the wire […]

-

Development and application of sheet metal manufacturing industry

Sheet metal manufacturing is the blanking or cold and hot forming of sheet metal materials, aluminum profiles and pipe fittings without changing their cross-sectional characteristics. Then the assembly is carried out by means of electric welding, riveting and screw connection, and the production and manufacturing mode of the specified metal structure is produced. The key […]

-

Difficulties in aluminum welding

Very easy to oxidize. In the air, aluminum is easily combined with oxidation to form a dense aluminum oxide film (about 0.1-0.2um thick) , the melting point is high (about 2050 ℃), far exceeding the melting point of aluminum and aluminum alloys (about 600 ℃). The density of alumina is 3.95-4.10g/cm3, about 1.4 times that […]