Tag: sheet metal structural

-

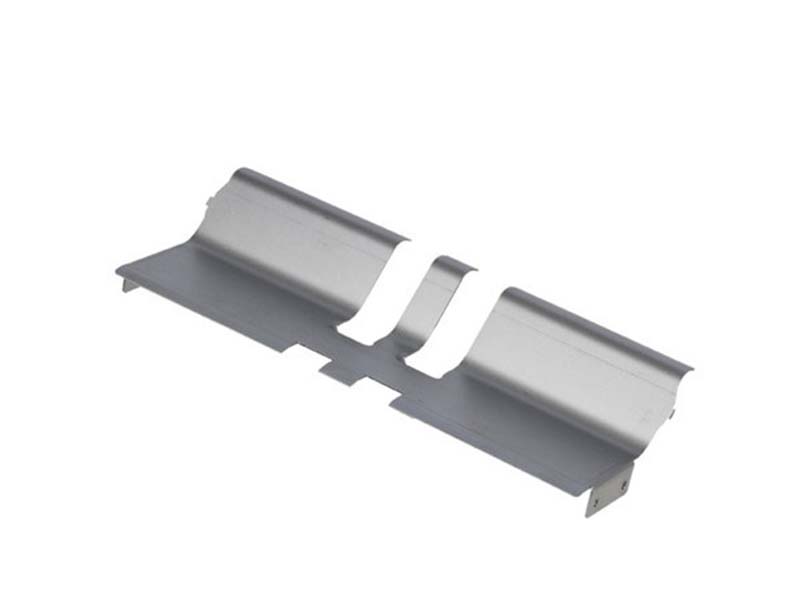

What is a sheet metal bracket?

One of the simplest and most cost-effective methods of manufacturing brackets, especially simple brackets such as corner brackets, is sheet metal manufacturing. The bracket is usually composed of two or more planes connected along an edge. The easiest way to make this object is usually to bend a flat object (i.e. a metal plate) at […]

-

Sheet metal case structural

Sheet metal is generally some sheet metal through manual or die stamping to produce plastic deformation to form the desired shape and size, and can further form more complex parts through welding or a small amount of machining. For example, chimneys, iron buckets, oil tanks, oil pots, ventilation pipes, funnel-shaped, etc. commonly used in families, […]

-

Customized outdoor communication cabinet

Outdoor communication cabinet is a kind of outdoor cabinet, which refers to the equipment made of metal or non-metallic materials under the direct influence of natural climate, which does not allow unauthorized operators to enter the cabinet for operation, and provides outdoor physical working environment and safety system for wireless communication stations or wired network […]

-

Requirements for sheet metal cabinet design

When designing the sheet metal cabinet, we should first clarify the design performance of the sheet metal cabinet, and on this basis, use various new process design sketches, specify the size and structure, and determine the strength to make the technical parameters of the cabinet meet the design requirements. Give full play to the performance […]

-

Customer requirements for sheet metal chassis processing

Materials. The plastic of the front panel of the good chassis is made of ABS engineering plastic, which is firm and stable. If the plastic used in the chassis is not hard or brittle enough, it is easy to crack, and there will certainly be quality problems. The steel plate shall be at least 0.8mm, […]

-

What factors affect the quality of sheet metal chassis?

Generally speaking, the basic equipment of sheet metal processing factory includes plate shears, CNC punches, laser plasma, water jet cutting machines, compound machines, bending machines and various auxiliary equipment, such as uncoilers, leveling machines, deburring machines, spot welding machines, etc. Metal plate processing is called sheet metal processing. Specifically, for example, using plates to manufacture […]

-

Aluminum sheet metal chassis

The density of aluminum is very small, only 2.7 grams / cubic centimeter. The specific heat capacity of aluminum is 0.88*1000 j/ (kg* ℃), and the density of steel is 7.9 g / cubic centimeter. The specific heat capacity is about 0.46*1000j/ (kg* ℃) in terms of density, steel is nearly three times that of […]

-

Scratch on the surface of metal chassis

1.The factors causing the scratch on the processing surface of sheet metal chassis are relatively complex and revolve around the whole process of commodity manufacturing, but they can be generally divided into two categories: one is the scratch of commodities during production, and the other is the scratch caused by freight logistics in the production […]

-

Sheet metal operation enclosure

The working casing is generally used in the environment with poor conditions. There are many places such as noise and dust in sheet metal processing plants. The part of the machine board is divided into two parts, which are represented in the form of a basic CPU card. Foreword: the working machine is generally used […]

-

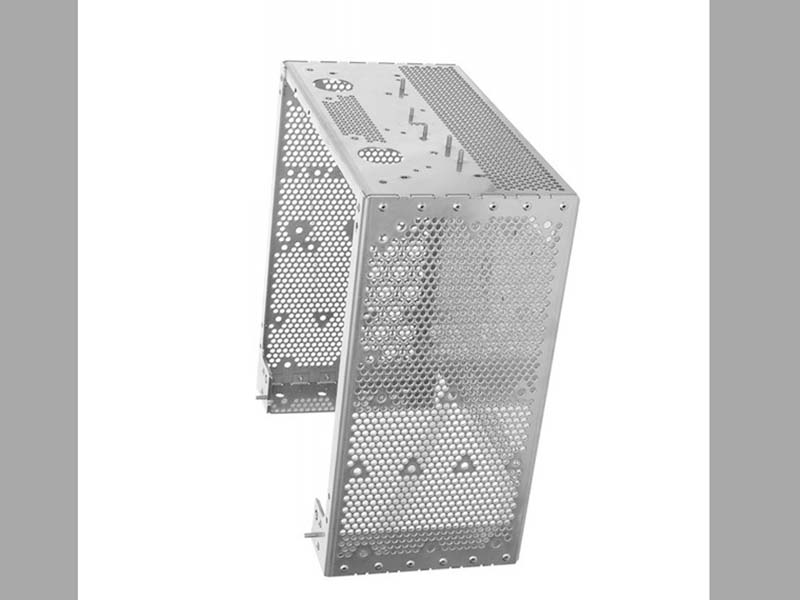

Sheet metal network cabinet

Network cabinet is a rectangular cabinet composed of frame and cover plate. It can install switches, optical fiber adapters, optical fiber distribution frames and other equipment in one cabinet. It has the properties of electromagnetic isolation, noise isolation, ventilation and heat dissipation, anti-vibration, anti-corrosion and so on, and can ensure the stable and reliable work […]