https://www.sheetmetalxj.com/

JIATONG XJ Precision Sheet Metal Fabrication

-

Sheet Metal Powder Spray

Sheet metal powder spray, often referred to as powder coating, is a finishing process in which a dry, powdered paint is applied to a metal surface. The powder is typically applied electrostatically and then cured under heat to form a hard, durable finish. Here’s an overview of the process and its benefits: Powder Coating Process […]

-

How the Defects for Sheet Metal Parts Could be Avoided?

Avoiding defects in sheet metal parts involves a combination of proper planning, tool maintenance, process control, and quality assurance. Here are some strategies to prevent common sheet metal defects: Burrs Use sharp, well-maintained cutting tools. Implement proper cutting speeds and feeds. Apply deburring processes such as tumbling, grinding, or manual deburring after cutting. Wrinkling Optimize […]

-

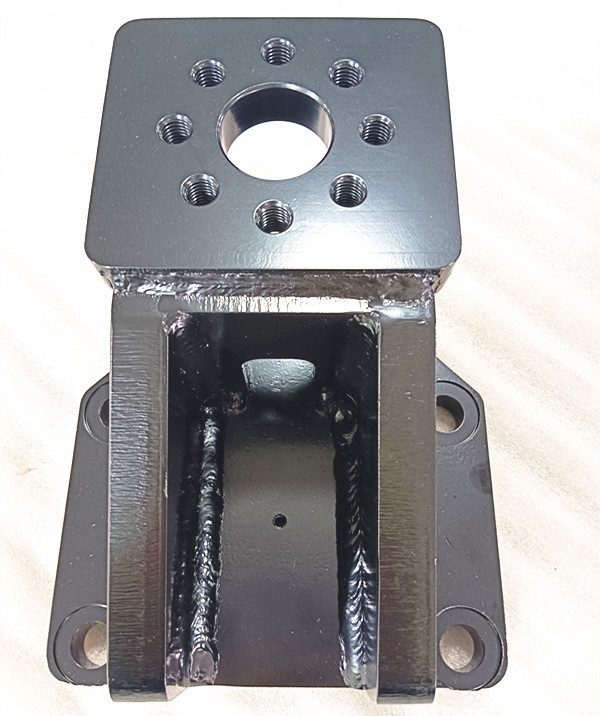

How to Avoid Sheet Metal Welding Defects?

Avoiding defects in sheet metal welding involves careful preparation, appropriate technique, and thorough inspection. Here are some strategies to minimize welding defects: 1. Proper Material Selection Quality of Material: Use high-quality sheet metal with minimal impurities. Appropriate Thickness: Ensure the sheet metal thickness is suitable for the welding process and application. 2. Surface Preparation Clean Surface: Remove contaminants […]

-

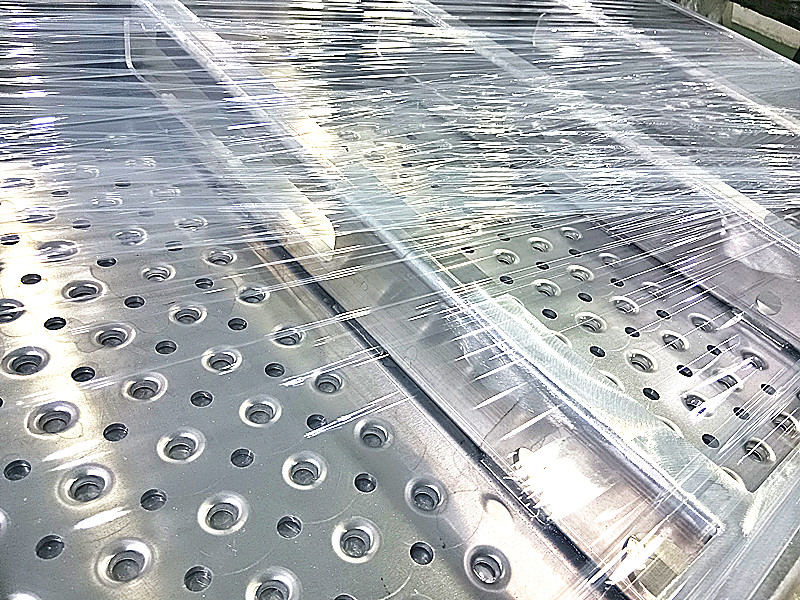

Sheet Metal Manufacturing

Sheet metal manufacturing is a versatile process used in the creation of various products and components made from thin, flat pieces of metal. This process involves several key steps and techniques: 1. Material Selection Common Metals: Steel, aluminum, brass, copper, tin, nickel, and titanium. Criteria: Strength, flexibility, weight, corrosion resistance, and cost. 2. Cutting Methods: […]

-

Sheet Metal Welding Techniques

Welding sheet metal requires techniques that minimize distortion and ensure strong, clean joints. Here are some commonly used techniques: TIG (Gas Tungsten Arc Welding): Advantages: Provides precise control over heat input, suitable for thin metals (0.5mm to 4mm), produces clean welds with minimal spatter. Considerations: Requires skill due to precise control needed, slower process compared […]

-

What are the Main Sheet Metal Welding Techniques?

Sheet metal welding is a common process in metal fabrication where two or more pieces of metal are joined together using heat, pressure, or both. This process is essential in various industries, including automotive, aerospace, construction, and manufacturing. Here are some key points about sheet metal welding: Types of Welding Processes: Several welding processes are […]

-

Main Sheet Metal Bending Brands

Several brands are well-known for manufacturing sheet metal bending equipment and tools. Some of the main brands in this industry include: Trumpf: Trumpf is a leading manufacturer of sheet metal bending machines, including press brakes and bending automation solutions. They offer a wide range of high-precision machines known for their reliability, accuracy, and innovative features. […]

-

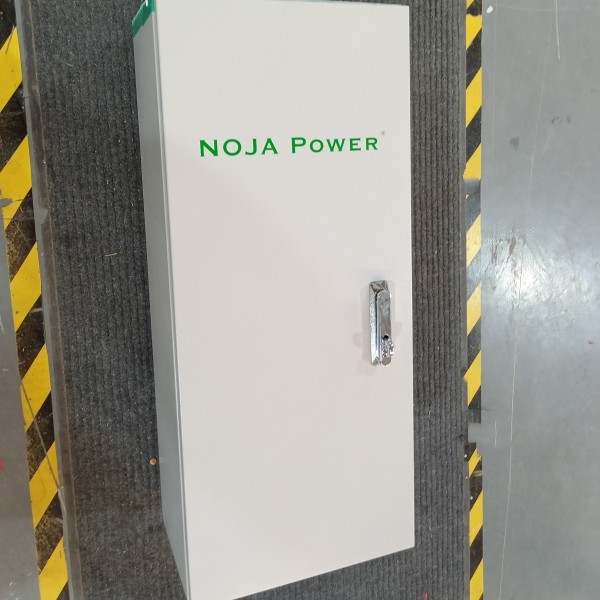

Features and Applications of Customized Distribution Boxes

Compared with the traditional distribution box, the customized distribution box has greater flexibility in many aspects such as appearance, size and electrical interior, and can be designed and produced according to the needs of different customers. Common features include: 1. Appearance size: Customized distribution boxes can be designed in any size according to different occasions, […]

-

What are the Advantages of Processing of Dongguan Jiatong Precision Hardware Products Co.?

I. Equipment and technology: Dongguan Jiatong Precision Hardware Products Co., Ltd. has a group of experienced and skilled team, and is also equipped with advanced sheet metal equipment and tools. We have a series of sheet metal processing equipment such as precision CNC punching machines, CNC bending machines, CNC shearing machines, etc., which can meet […]

-

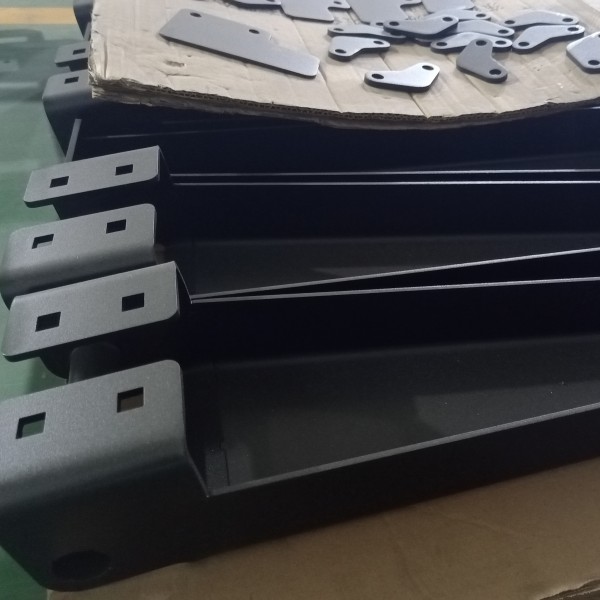

What do you Know about Sheet Metal Brackets?

Sheet metal brackets can play the role of supporting various equipment to ensure that the equipment can run stably and avoid malfunction due to shaking; they can fix the equipment in a certain position to avoid accidents caused by displacement when the equipment is running; they can play the role of beautifying the equipment, increasing […]

Got any book recommendations?