https://www.sheetmetalxj.com/

JIATONG XJ Precision Sheet Metal Fabrication

-

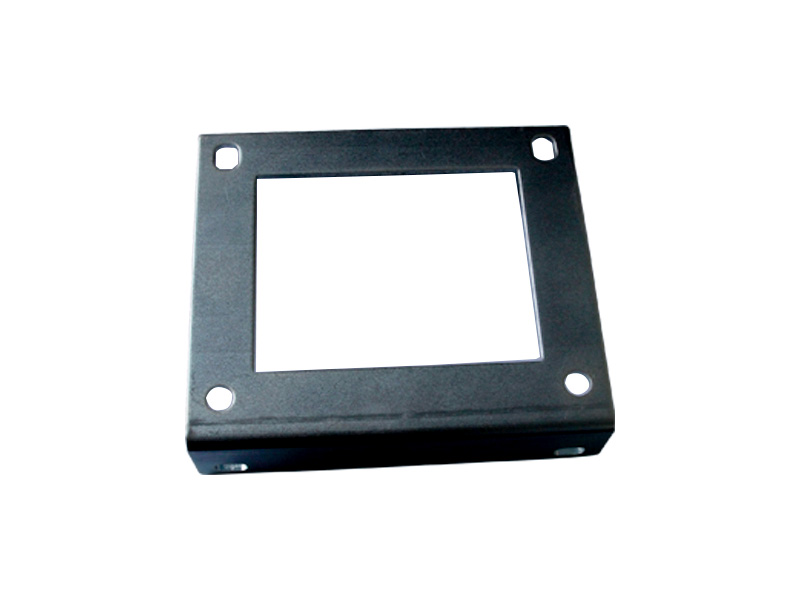

Common problems and causes of sheet metal processing and stamping parts processing

Common problems and causes of sheet metal processing and stamping parts processing: 1 burr: the excess material is not completely left during stamping or corner cutting, and burr appears under the steel plate section. When the burr height is greater than 0.2mm according to the section, the iron powder will damage the die and produce […]

-

Deep drawing

Deep drawing is a kind of stamping processing method to punch a certain shape of flat blank into various open hollow parts, or take the open hollow parts as blank to reduce the diameter and increase the height. Shape of drawing parts The shape of drawing parts(custom sheet metal parts) shall be as simple and […]

-

Six advantages of CNC cutting machine in sheet metal industry

CNC cutting machine is the product of the development of modern science. It is also a technological revolution in sheet metal processing, and has brought revolutionary ideas to sheet metal manufacturing and processing. Laser cutting technology and CNC cutting machine equipment are being familiar and accepted by the majority of plate processing enterprises. With its […]

-

Wire drawing

Wire drawing can be made into straight lines, random lines, threads, ripples and spiral lines according to the needs of decoration. Straight line wire drawing refers to machining straight lines on the surface of aluminum plate by mechanical friction. The utility model has the dual functions of removing scratches on the surface of aluminum plate […]

-

What should be paid constant attention to and ensured when bending sheet metal parts?

1.Avoid bending failure due to the failure of material pressing at the bending root When bending sheet metal, other features are often too close to the sheet metal, resulting in failure to press and unable to bend or serious bending deformation. Generally speaking, a distance of at least twice the thickness of the sheet metal […]

-

What is surface treatment?Why should surface treatment be carried out?

1)What is surface treatment? Surface treatment: change the shape, chemical composition and organizational structure of the product surface and near surface area by the most economical and effective method, effectively improve and improve the decorative performance(Decorative sheet metal cabinet), corrosion resistance and wear resistance of the product, and prolong the service life of the product. […]

-

Surface treatment of aluminum – oxidation and anodizing

Aluminum oxide (coloring) Aluminum and aluminum alloys are more and more widely used because they are easy to form and lighter than other metal materials. The chemical properties of aluminum and aluminum alloy are very active, so certain protective treatment must be carried out: such as electroplating, spraying, organic protection and oxidation treatment. Oxidation treatment […]

-

Characteristics of sheet metal manufacturing industry

Because most sheet metal manufacturing is the production and manufacturing of cold or hot separation and forming of raw materials without changing the cross-sectional characteristics of sheet metal materials, aluminum profiles and pipe fittings. Moreover, the produced metal material causes plastic deformation below the manufacturing hardening temperature, so it does not cause cutting. It can […]

-

A summary of some bending elements

Bending is a stamping process that uses pressure to force the material to produce plastic deformation, so as to form a certain angle and curvature shape. Common bending includes V-shaped bending, Z-shaped bending and reverse bending. The following is a summary of some bending elements : Bending height The bending height shall be at least […]

-

Quality and specification of grinding

1) Grinding and polishing quality After grinding, the surface of the parts shall be free of unevenness, burr, concave hole and trachoma. After polishing, the overall surface shall be smooth. The surface of stainless steel products or welding parts(custom sheet metal parts) shall be treated with XX mesh wire drawing. After wire drawing, the wire […]

Got any book recommendations?