First of all, we need to know what is sheet metal? The remarkable feature of sheet metal is that the thickness of the same part is the same. According to the definition, sheet metal is a cold working process of sheet metal, including shearing, punching / cutting / compounding, folding, riveting, splicing, forming (such as automobile body), etc. The surface treatment of sheet metal is mainly in two ways: plastic spraying (powder spraying) and oil spraying. Large parts are usually sprayed with plastic, and small parts can be sprayed with oil. This is determined by the characteristics of the process.

Compared with other cutting processes, sheet metal processing and cutting technology has the advantages of high speed, high precision and high adaptability, fine cutting seam, small heat affected zone (small deformation), good cutting end face quality, no noise, weld zone group and performance close to the base metal; Moreover, the processing only needs simple fixtures and no molds. It can replace the processing method of punching with complex molds, which can greatly shorten the production cycle and reduce the production cost. Now let’s talk about the characteristics of sheet metal design.

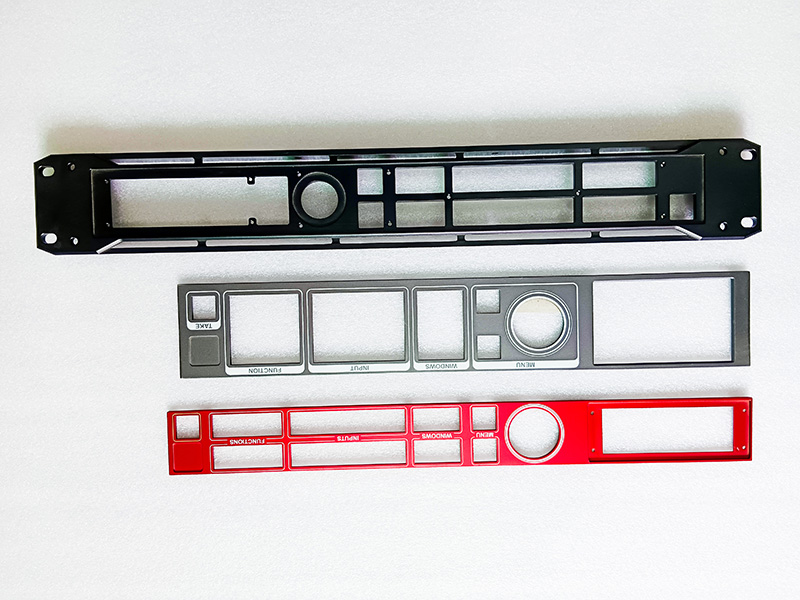

Battery Bracket Holder | Jbod Storage Enclosure | Storage Server Chassis

The sheet metal design needs to conform to its process characteristics, and generally should have the following characteristics.

- Cost rationality: the first consideration for the rationality of sheet metal design is the cost. The positioning of the high, middle and end of the product should be clear, which involves material selection, process layout, surface treatment and decoration, so as to achieve the “rationality” of the cost;

- For the rationality of modeling, sheet metal has its special processing technology, which should adapt to the modeling design and minimize the curve design;

- The rationality of material selection, fully consider the factors such as product application and environment, and reasonably select raw materials and surface treatment process;

- Rationality of structure: sheet metal focuses on stiffness rather than strength, and the section design of bending parts should be reasonable;

- Rationality of process: that is, the manufacturability of the product (which needs to be exercised in the production line), such as the avoidance of bending, the design of welding joint and weld can not affect the deformation after welding, the rationality of the number, size and edge distance of punching mesh can affect the flatness, the edge of electroplated parts can not be crushed, the assembly and disassembly sequence of workpieces can not interfere with each other, and the assembly can not be affected.

It should be noted that the structural design of sheet metal parts mainly plays three roles: first, the load-bearing parts of the equipment need to bear the gravity of the main body (including the force generated during its movement); Second, the movable connector of the equipment needs to operate in coordination and consistency according to the requirements of the application software; The third is the external framework of the main body, which needs to reflect the characteristics of flexible hardware. Therefore, sheet metal equipment needs to be comprehensively designed in combination with materials, mechanics, mechanical engineering, industrial design and other disciplines in order to meet its functional and appearance process requirements.

QUICK LINKS: FAQ | 95r Battery E70 Bracket | Powder Coat Fine Texture Black Hot Rolled Pickled Metal Stands | Switch Mounting Bracket | Aluminum Rack Panels | Racing Lawn Mower Parts | Battery Hold Down Brackets | OEM Custom Radiator Support Bracket | Custom Metal Fabrication |TV Back Panel| Custom Rackmount PC |

Leave a Reply