Category: MFG Guide

-

What are the rules for sheet metal holes?

When designing or working with sheet metal, certain rules govern the creation of holes to ensure structural integrity, manufacturability, and ease of production. Here are the general rules for sheet metal holes: 1. Minimum Hole Diameter The minimum diameter for holes should typically be equal to or greater than the thickness of the sheet metal. […]

-

What are the three 3 types of metal fabrication?

Metal fabrication generally involves creating metal structures and components through various processes. The three primary types of metal fabrication are: Cutting: This involves slicing or shearing metal to create desired shapes or sizes. Cutting can be done using various tools and methods, including lasers, plasma, water jets, saws, and shears. Forming: Forming involves bending or […]

-

How do you inspect sheet metal parts?

Inspecting sheet metal parts involves a combination of visual inspections, dimensional measurements, and non-destructive testing (NDT) methods. The goal is to ensure that the parts meet the required specifications, are free from defects, and conform to quality standards. Here’s an overview of common inspection techniques for sheet metal parts: 1. Visual Inspection Surface Defects: Look […]

-

What is the cheapest way to manufacture metal parts?

The cheapest way to manufacture metal parts depends on factors such as the type of metal, the complexity of the part, the production volume, and the required tolerances. Below are some cost-effective manufacturing methods based on these factors: Sheet metal fabrication is considered a lower cost method for manufacturing certain types of parts. It’s simple, right? […]

-

What are the different types of sheet metal welding?

Sheet metal welding involves joining thin sheets of metal using various welding techniques. The choice of welding method depends on factors such as the type of metal, the thickness of the sheet, and the desired strength of the weld. Here are some common types of sheet metal welding: 1. Tungsten Inert Gas (TIG) Welding Description: […]

-

What is the most important thing in welding?

The most important thing in welding is achieving a strong, high-quality weld. A successful weld ensures that the materials being joined are securely bonded, capable of withstanding stress, and free from defects. To achieve this, several factors must be considered: Proper Technique: The welder must apply the correct welding technique for the materials and type […]

-

What welding is used for sheet metal?

Several welding methods can be used for sheet metal, depending on the thickness, material, and application. The most common welding techniques for sheet metal include: 1. TIG Welding (Tungsten Inert Gas) Best for: Thin sheet metal and non-ferrous metals like aluminum, magnesium, and copper. Advantages: Precise control, high-quality welds with minimal distortion. Disadvantages: Slower and […]

-

What does a sheet metal fabricator do?

A sheet metal fabricator is a skilled tradesperson who works with thin sheets of metal to create various structures and components. Their job involves cutting, shaping, bending, and assembling metal sheets into products or parts used in construction, manufacturing, and other industries. Here are some key tasks a sheet metal fabricator typically performs: Measuring and […]

-

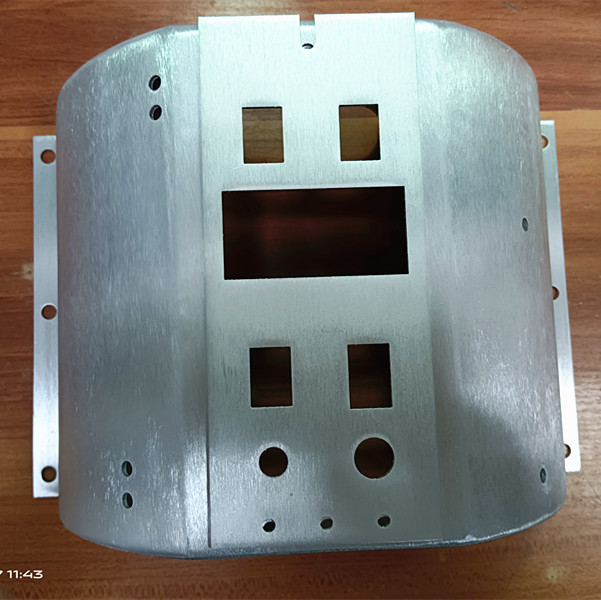

What are the benefits of using a sheet metal enclosure?

Sheet metal enclosures offer several benefits that make them a popular choice for housing various types of equipment, electronics, and machinery. Here are some key advantages: 1. Durability and Strength Impact Resistance: Sheet metal enclosures are highly durable and resistant to physical impact, which helps protect the contents from damage. Corrosion Resistance: Depending on the […]

-

Sheet Metal Enclosure Design Tips

Designing a sheet metal enclosure requires attention to detail and consideration of various factors to ensure the final product is functional, manufacturable, and cost-effective. Here are some key tips to guide you through the process: 1. Material Selection Choose the right material: Common materials include aluminum, stainless steel, and cold-rolled steel. Each has its strengths, […]