Category: Uncategorized

-

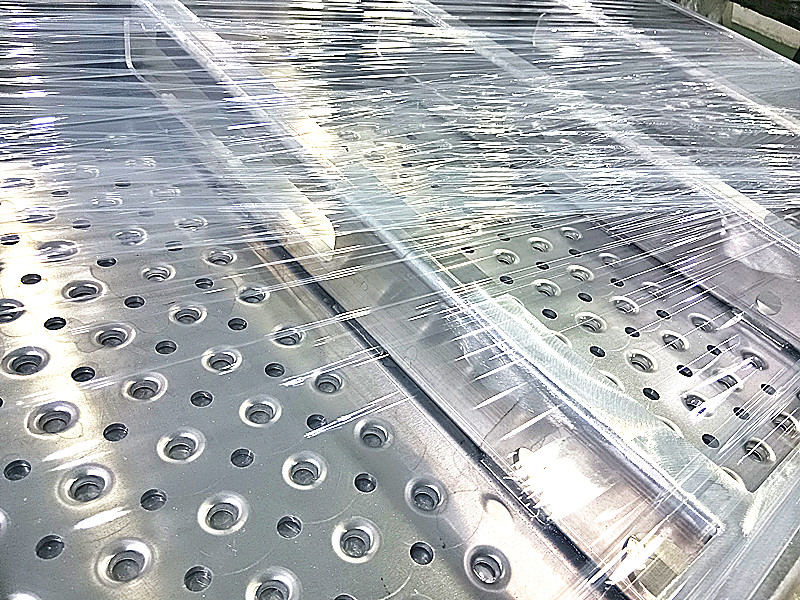

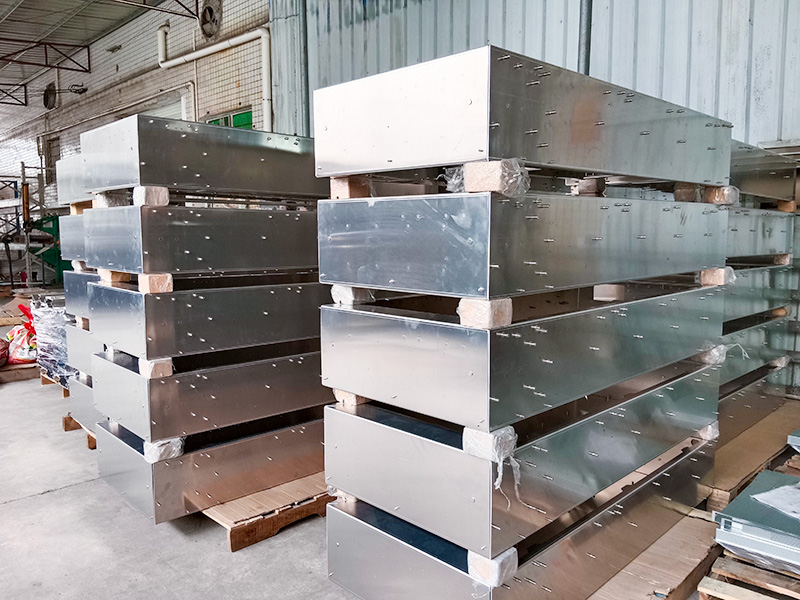

General inspection standard for sheet metal chassis

The sheet metal chassis is not allowed to be tilted or partially tilted with the naked eye. The verticality between the frame column and the base is less than 1.5mm. During the inspection, the upper surface of the base is taken as the benchmark, and the inner edge surface of the upper end of the […]

-

Common failure modes and prevention of riveting

1) Riveting looseness: the riveting is disengaged under the use of tensile force, shear force or other cyclic loads. Cause: the flanging is not fully opened, the flanging pressing area is too narrow, and the flanging is broken. Prevention: a. the height of budding shall be in place to avoid budding into continuous flower opening […]