Category: MFG Guide

-

How the Defects for Sheet Metal Parts Could be Avoided?

Avoiding defects in sheet metal parts involves a combination of proper planning, tool maintenance, process control, and quality assurance. Here are some strategies to prevent common sheet metal defects: Burrs Use sharp, well-maintained cutting tools. Implement proper cutting speeds and feeds. Apply deburring processes such as tumbling, grinding, or manual deburring after cutting. Wrinkling Optimize […]

-

How to Avoid Sheet Metal Welding Defects?

Avoiding defects in sheet metal welding involves careful preparation, appropriate technique, and thorough inspection. Here are some strategies to minimize welding defects: 1. Proper Material Selection Quality of Material: Use high-quality sheet metal with minimal impurities. Appropriate Thickness: Ensure the sheet metal thickness is suitable for the welding process and application. 2. Surface Preparation Clean Surface: Remove contaminants […]

-

Sheet Metal Welding Techniques

Welding sheet metal requires techniques that minimize distortion and ensure strong, clean joints. Here are some commonly used techniques: TIG (Gas Tungsten Arc Welding): Advantages: Provides precise control over heat input, suitable for thin metals (0.5mm to 4mm), produces clean welds with minimal spatter. Considerations: Requires skill due to precise control needed, slower process compared […]

-

What are the Main Sheet Metal Welding Techniques?

Sheet metal welding is a common process in metal fabrication where two or more pieces of metal are joined together using heat, pressure, or both. This process is essential in various industries, including automotive, aerospace, construction, and manufacturing. Here are some key points about sheet metal welding: Types of Welding Processes: Several welding processes are […]

-

Main Sheet Metal Bending Brands

Several brands are well-known for manufacturing sheet metal bending equipment and tools. Some of the main brands in this industry include: Trumpf: Trumpf is a leading manufacturer of sheet metal bending machines, including press brakes and bending automation solutions. They offer a wide range of high-precision machines known for their reliability, accuracy, and innovative features. […]

-

Procedures of Fabricating Custom Sheet Metal Boxes?

Custom sheet metal boxes can be fabricated to meet specific requirements and dimensions for a variety of purposes. Here are some basic steps for creating custom sheet metal boxes: Determine the specifications: Identify the size, shape, and material type required for the box. Consider any additional requirements, such as finishes or coatings, and any necessary […]

-

How to Find the Right Metal Supplier for Your Next Project

Finding the right sheet metal supplier quickly can be a daunting task, but there are some steps that you can take to make sure you find the best one. First and foremost, it is important to make sure the supplier has quality parts [1]. You can easily find out about the quality of parts by […]

-

What is the General Tolerance for Sheet Metal Fabrication?

Sheet metal processing is the most commonly used metal processing method nowadays. In the process of parts processing, the size of produced sheet metal parts cannot be absolutely accurate due to various factors such as processing accuracy of machinery and equipment, die wear and tear, processing errors, etc. In order to ensure the availability of […]

-

Sheet Metal Design Basics

With the widespread use of sheet metal, sheet metal design has become a very important part of the product development process. What should I pay attention to in sheet metal design? Sheet metal design generally has the following design points. (1) Sheet metal design should first pay attention to the relationship between the sheet metal […]

-

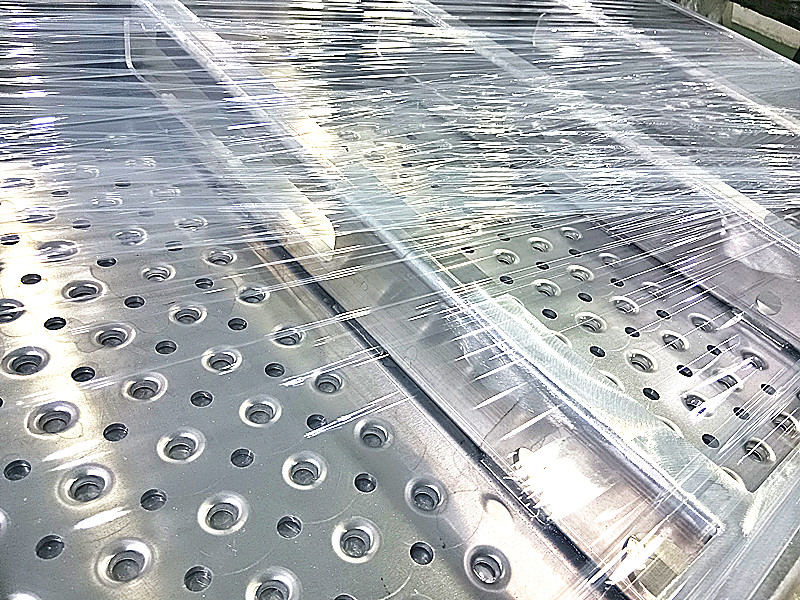

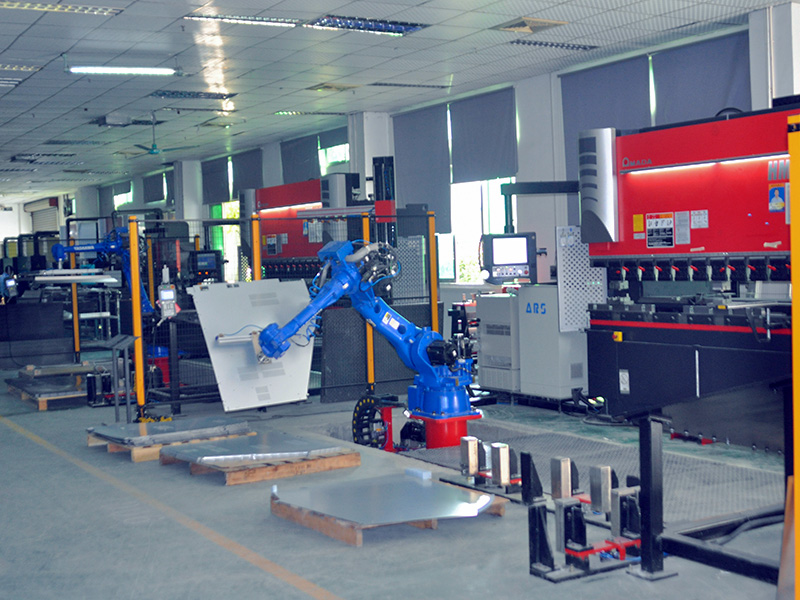

Sheet Metal Manufacture and Quality Control

Sheet metal parts are important components of injection molding machines, not only for their complex structure but also for their beautiful appearance and safety protection. The main processes are: cutting, shearing, punching, folding, welding, splicing, molding, spraying, etc. It is the last process of injection molding machine assembly. Due to the complicated process, the outsourcing […]