Tag: sheet metal structural

-

Common sense of sheet metal processing

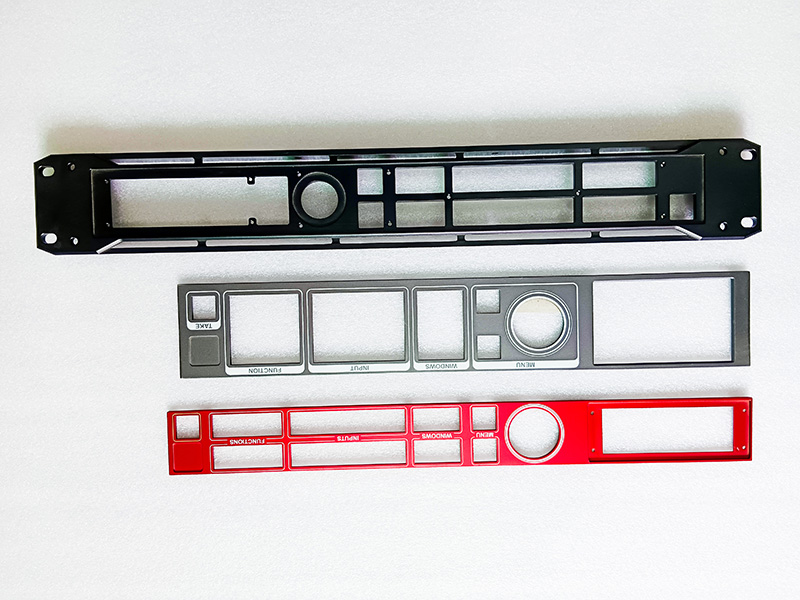

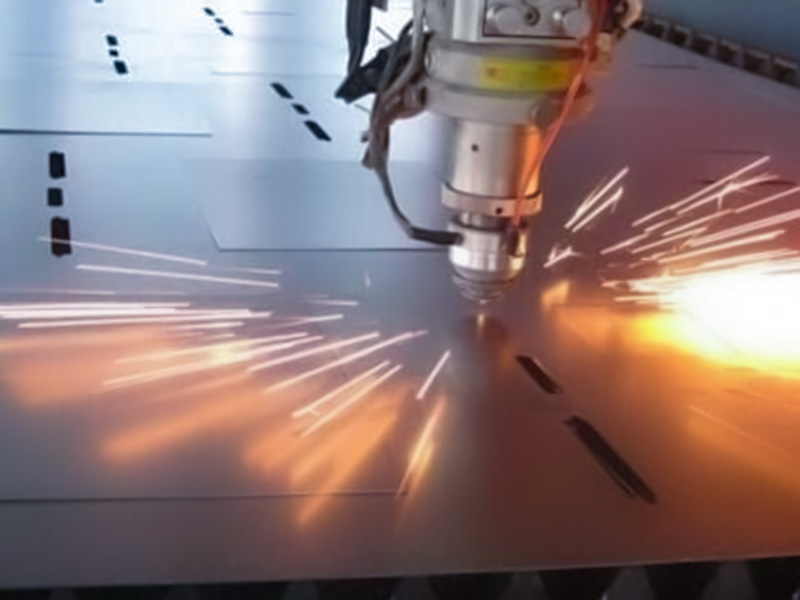

After getting the drawings, select different blanking methods according to different opening drawings and batches, including laser, CNC punch, plate shearing, die, etc. Then open it according to the drawing. Placing the worktable next to the NC and laser is conducive to placing the plate on the machine for processing and reducing the workload of […]

-

Advantages and disadvantages of sheet metal processing stamping parts

advantage low cost Sheet metal stamping is a low-cost manufacturing technology. Its cost is usually lower than other methods, making it an ideal choice for small businesses with limited budgets. Since this method does not require molds or tools to create assemblies or parts, many people believe that it is also low cost. However, the […]

-

How to improve the machining accuracy of sheet metal machining?

Whether it is a sheet metal processing manufacturer or an individual, the sheet metal processing accuracy may be unsatisfactory. Therefore, in order to better ensure the power, reduce material waste and reduce labor, we need to improve the machining accuracy of sheet metal machining. Do you know how to improve the machining accuracy of sheet […]

-

Common problems of sheet metal processing stamping parts

The sheet metal stamping process converts hot-rolled or cold-rolled steel plates into the shape needed to make your parts. This technology allows a large number of parts to be produced at the same time, but it can also cause about 15% of raw materials to become waste. The equipment used in this method requires less […]

-

Methods to prevent corrosion of sheet metal shell

In the production of sheet metal shell, sometimes no matter what material we use, the sheet metal shell may be corroded after long-term use due to the problem of wet weather. When this phenomenon occurs, it will undoubtedly cause great inconvenience to us. In order to effectively solve this problem, we can greatly reduce the […]

-

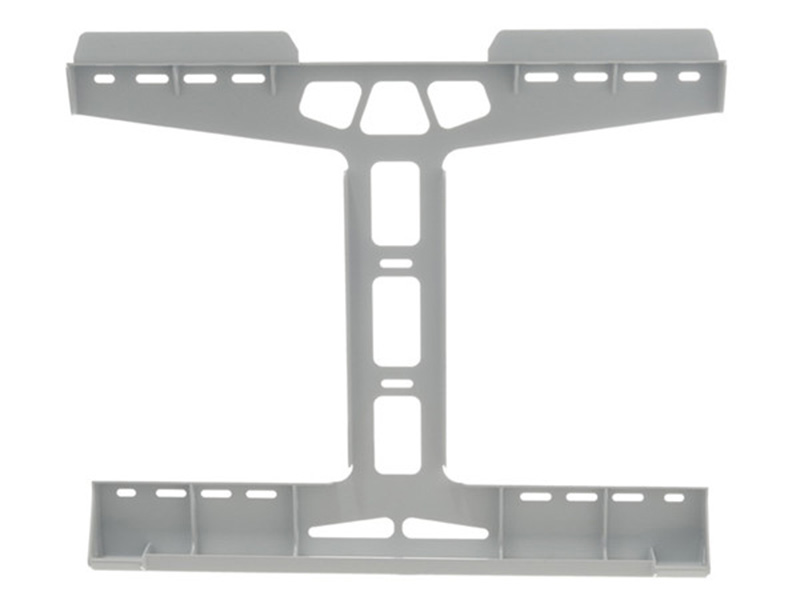

Characteristics and advantages of sheet metal design

First of all, we need to know what is sheet metal? The remarkable feature of sheet metal is that the thickness of the same part is the same. According to the definition, sheet metal is a cold working process of sheet metal, including shearing, punching / cutting / compounding, folding, riveting, splicing, forming (such as […]

-

Hydraulic sheet metal bending machine

The bending radius of sheet metal is a value required in the sheet metal drawing, which is difficult to determine in actual processing. In fact, the bending radius of the sheet metal is related to the material thickness, the pressure of the NC bending machine and the width of the lower die groove of the […]

-

How to determine the bending sequence of sheet metal bending?

General bending sequence Short side first and then long side: Generally speaking, when there are bends on all four sides, the short side first and then the long side is conducive to the processing of workpieces and the assembly of bending molds. First the periphery and then the middle: under normal circumstances, it is generally […]

-

Process of sheet metal parts from making to forming

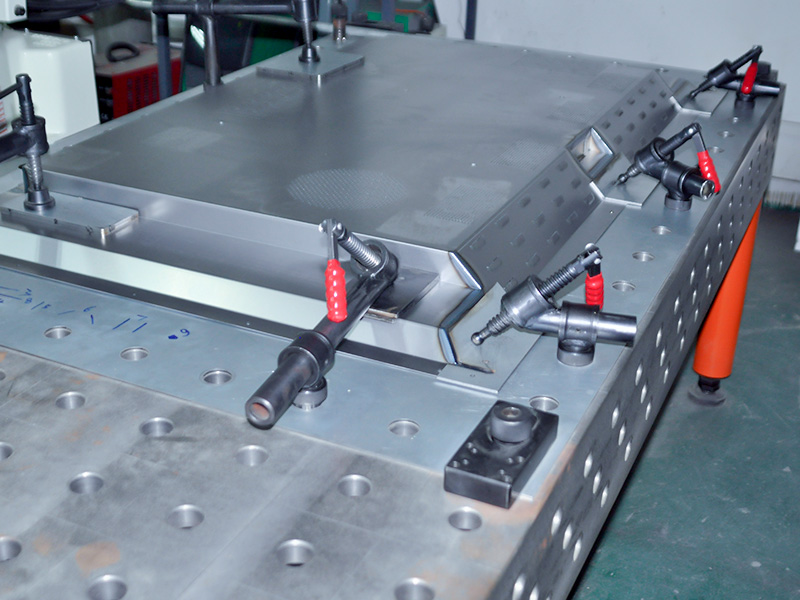

1、 Blanking. After the drawing is successful, the blanking methods shall be determined according to the expansion drawing, batch gap and technical requirements, including laser, CNC punch, plate shearing, die and so on. The NC punch is affected by the cutting tool. For the processing of some special-shaped workpieces and irregular holes, it should take […]

-

Four basic cold processing links to optimize sheet metal design

Generally, sheet metal parts have obvious advantages in strength, weight and cost, and have better point-to-point performance than traditional parts. Therefore, up to now, sheet metal parts have been gradually applied in China’s high-tech fields such as electronics and communication. At the same time, people have gradually put forward higher requirements for the quality and […]