Inspecting sheet metal parts involves a combination of visual inspections, dimensional measurements, and non-destructive testing (NDT) methods. The goal is to ensure that the parts meet the required specifications, are free from defects, and conform to quality standards. Here’s an overview of common inspection techniques for sheet metal parts:

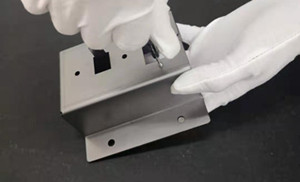

1. Visual Inspection

Surface Defects: Look for visible defects such as scratches, dents, cracks, corrosion, or discoloration.

Edges and Bends: Inspect the edges for burrs, sharpness, or deformations. Verify that bends are consistent and smooth.

Weld Quality: If the part has welds, check for proper penetration, uniformity, and the absence of splatter or porosity.

2. Dimensional Inspection

Calipers and Micrometers: Use these tools to measure thickness, length, width, hole diameters, and other critical dimensions.

Coordinate Measuring Machine (CMM): A CMM can precisely measure complex geometries and compare them to CAD models or design specifications.

Laser Scanning: Laser scanning can create a 3D model of the part, allowing for detailed comparison with design specifications.

Go/No-Go Gauges: These are used for specific tolerances to quickly verify whether a part meets the required dimensions.

Passing Certification ISO9001 2015 Quality Control and Inspection Facilities and Methods:Two-dimension detector, Projector, Height gauge, Paint adhesion detector, Paint color difference detection, Paint thickness test, Angle test, Thread gauge, Microcalliper Gauge.etc.

3. Flatness and Alignment Checks

Surface Plates: Place the part on a surface plate to check for flatness. If there is any rocking, the part is not flat.

Height Gauges: Used to measure the height of various features and ensure alignment across the part.

4. Form and Fit Verification

Bend Radius Measurement: Verify the bend radius to ensure that it meets design requirements.

Fit Check: Assemble the part with mating components to ensure it fits properly.

5. Non-Destructive Testing (NDT)

Ultrasonic Testing: Used to detect internal defects such as cracks, voids, or inclusions.

Magnetic Particle Inspection (MPI): Effective for detecting surface and near-surface defects in ferromagnetic materials.

Dye Penetrant Inspection (DPI): A method for detecting surface-breaking defects. The part is coated with a dye, and after a short period, the excess dye is removed, leaving the dye in any cracks or defects.

Radiography (X-ray): Used to inspect internal features or identify internal defects.

6. Thickness and Coating Inspection

Ultrasonic Thickness Gauges: These are used to measure the thickness of the sheet metal without cutting it.

Coating Thickness Measurement: If the sheet metal has a protective coating (e.g., paint, anodizing), a coating thickness gauge can ensure that it meets the specified thickness.

7. Material Testing

Hardness Testing: Measure the hardness of the material to ensure that it has been processed correctly.

Tensile Testing: A sample may be subjected to tensile testing to verify the material’s strength and ductility.

8. Documentation and Reporting

Inspection Reports: Record all inspection results, including dimensional data, NDT findings, and visual inspection results.

Conformance Certificates: Provide certificates of conformance if the part meets all specified requirements.

Best Practices

Inspect at Various Stages: Inspections should occur at different stages of the manufacturing process (e.g., after forming, bending, welding) to catch defects early.

Standard Operating Procedures (SOPs): Follow SOPs for each inspection method to ensure consistency and reliability.

Training: Ensure inspectors are properly trained to recognize defects and use inspection equipment accurately.

Regular inspections ensure that the final product is of high quality and meets the necessary standards for safety and performance.

Click sheet metal fabrication company china or china sheet metal forming manufacturers to learn more about sheet metal fabrication services.

For all your electrical enclosures from China, contact Sheet Metal Fabrication Companies in China JIATONG now.

From china metal enclosure manufacturers, china sheet metal manufacturing manufacturers – JIATONG

Leave a Reply