Distinguishing a professional sheet metal fabrication manufacturer involves assessing several key factors:

Experience and Expertise:

Years in Business: Long-standing manufacturers tend to have more experience and proven track records.

Specialization: Check if they specialize in the type of fabrication you need (e.g., automotive parts, electronics, construction).

Certifications and Standards:

ISO Certification: Look for ISO 9001 (quality management), ISO 14001 (environmental management), and other relevant certifications.

Industry-Specific Certifications: Depending on the industry, there may be specific standards like AS9100 for aerospace.

Technology and Equipment:

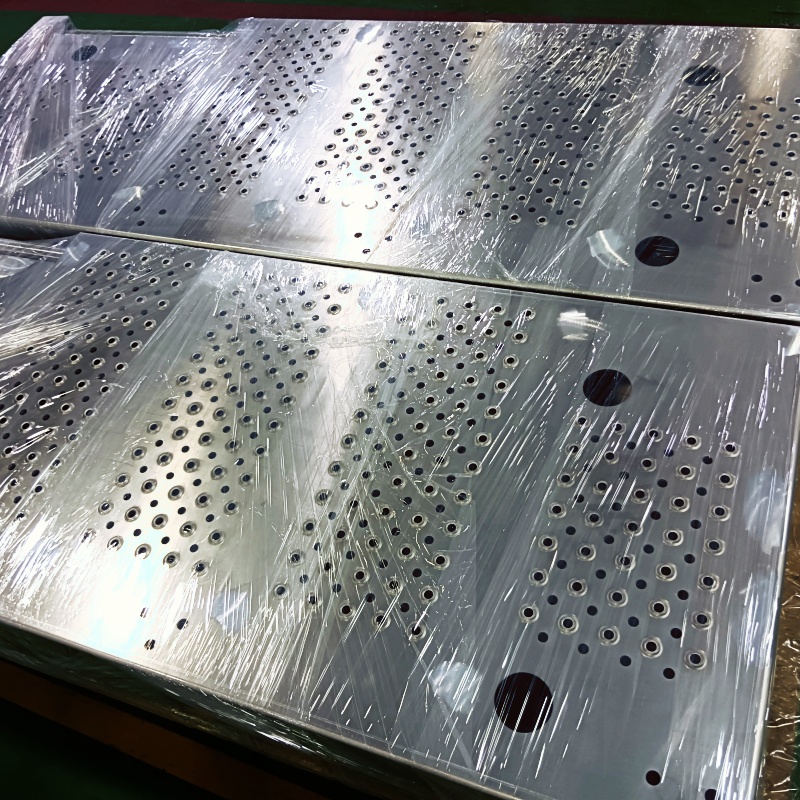

Modern Equipment: Ensure they use advanced machinery like CNC machines, laser cutters, and robotic welders.

Software: Check if they use modern CAD/CAM software for design and manufacturing processes.

Quality Control:

Inspection Processes: A good manufacturer will have rigorous inspection processes, including first article inspections (FAI), in-process inspections, and final inspections.

Testing Capabilities: They should be able to conduct various tests, such as material testing, dimensional accuracy checks, and surface finish inspections.

Capabilities and Capacity:

Range of Services: Look for a manufacturer that offers a full range of services, from design and prototyping to full-scale production and assembly.

Production Capacity: Ensure they can handle your volume requirements, whether it’s for small batch or mass production.

Reputation and References:

Client Testimonials: Read reviews and testimonials from previous clients.

Case Studies: Ask for case studies or examples of past projects similar to yours.

Lead Times and Flexibility:

Delivery Times: Assess their lead times for delivery and their ability to meet deadlines.

Flexibility: Check if they can handle changes in design or urgent orders without significant delays.

Cost and Value:

Pricing: Compare their pricing with other manufacturers, but also consider the value they offer in terms of quality, reliability, and service.

Value-Added Services: Consider additional services such as design assistance, finishing services, and logistics support.

Customer Service and Communication:

Responsiveness: A professional manufacturer will be responsive to inquiries and proactive in communication.

Technical Support: Check if they offer technical support during the design and manufacturing process.

Location and Logistics:

Proximity: Consider the location of the manufacturer in relation to your business for easier logistics and lower shipping costs.

Logistics Support: Ensure they can handle shipping and delivery efficiently.

By evaluating these aspects, you can better distinguish a professional and reliable sheet metal fabrication manufacturer that meets your specific needs.

Related Links:

china sheet metal fabrication manufacturers | sheet metal fabrication company china | china sheet metal fabrication companies | china sheet metal forming manufacturers | china sheet metal fabrication factory | china metal enclosure manufacturers | china sheet metal fabrication supplier | china custom sheet metal parts | china sheet metal parts company | china precision sheet metal manufacturer | china sheet metal parts manufacturers | china sheet metal manufacturing manufacturers | Folded Sheet Metal Box | Sheet Metal Fabrication Companies in China | Sheet Metal Parts Manufacturing China

Leave a Reply