Category: Technology News

-

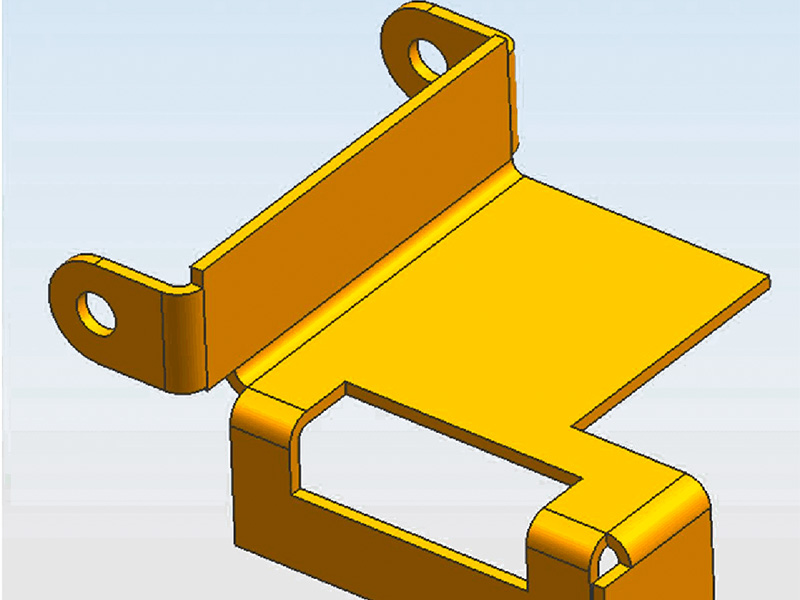

Bending problems to be considered in sheet metal design

The design needs to consider what is processing before forming and what is processing after forming. Considering that in the process of work production, some holes must be bent first and then processed: round holes, square holes, waist round holes, threads, etc. close to the bending edge need to be processed during blanking. If the […]

-

Design criteria of sheet metal structure

According to the problems encountered in the actual machining process, the problems needing attention in the structural design of sheet metal are discussed from the following aspects, and the corresponding design criteria are given. Selection criteria of sheet metal materials Sheet metal is generally used for the installation of equipment shell and electrical circuit, so […]

-

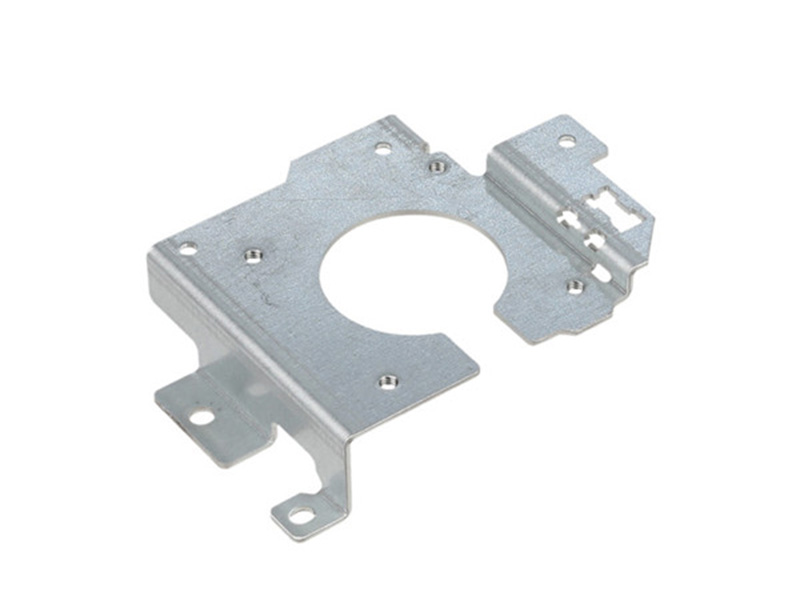

Process analysis of sheet metal structure design

Sheet metal processing is a comprehensive cold working process for sheet metal, including shearing, punching, cutting, folding, welding, riveting, etc. its remarkable feature is that the thickness of the same part is the same. Sheet metal is generally some sheet metal through manual or die stamping to produce plastic deformation to form the desired shape […]

-

Analysis on the current situation of sheet metal processing industry in China

R & D status with the development of industrial manufacturing technology and electronic information technology, the technical requirements for sheet metal processing products are also increasing. From 2011 to 2017, the number of patent applications in China’s sheet metal processing industry increased year by year; In 2014, the number of industrial patent applications reached the […]

-

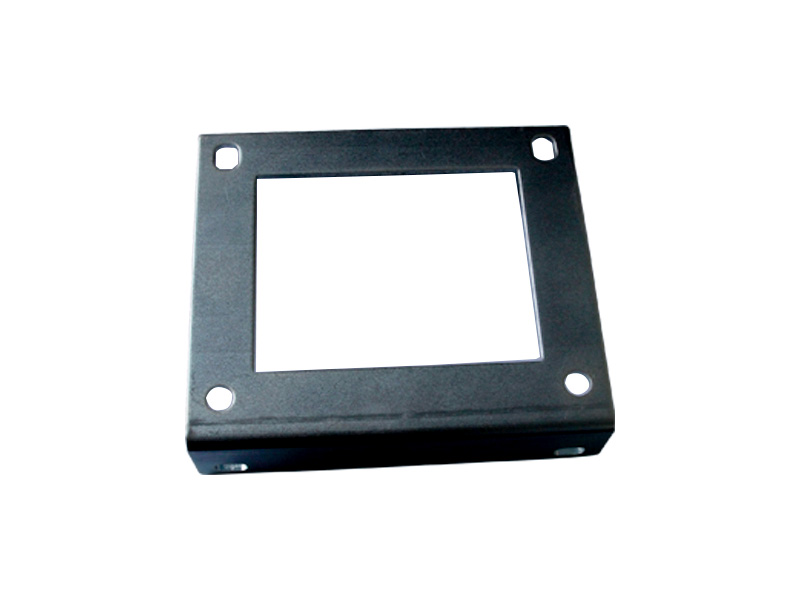

Requirements for painting and welding

Painting requirements Rust, scale, grease, dust, soil, salt and dirt must be removed from the surface of all steel parts to be painted before painting. Before derusting, remove grease and dirt on the surface of steel parts with organic solvent, alkali liquor, emulsifier and steam. The time interval between the surface to be […]

-

Process benchmarks of sheet metal products should be followed for assembly

According to the specified technical requirements, the process of matching and connecting parts or components to make them into semi-finished products or finished products(finished sheet metal brackets) is called assembly. In the manufacturing process(sheet metal manufacturer), in order to reduce the error, the following process benchmarks of sheet metal products should be followed for […]

-

What details should be paid attention to in the processing of sheet metal cabinet?

At present, in the processing industry, sheet metal cabinet processing is one of the more prominent processing forms, because the sheet metal cabinet products with good strength and long service life can well protect the sheet metal cabinet equipment, so as to prevent any damage to the inner parts. However, in order to better ensure […]

-

Common problems and causes of sheet metal processing and stamping parts processing

Common problems and causes of sheet metal processing and stamping parts processing: 1 burr: the excess material is not completely left during stamping or corner cutting, and burr appears under the steel plate section. When the burr height is greater than 0.2mm according to the section, the iron powder will damage the die and produce […]

-

Deep drawing

Deep drawing is a kind of stamping processing method to punch a certain shape of flat blank into various open hollow parts, or take the open hollow parts as blank to reduce the diameter and increase the height. Shape of drawing parts The shape of drawing parts(custom sheet metal parts) shall be as simple and […]

-

Six advantages of CNC cutting machine in sheet metal industry

CNC cutting machine is the product of the development of modern science. It is also a technological revolution in sheet metal processing, and has brought revolutionary ideas to sheet metal manufacturing and processing. Laser cutting technology and CNC cutting machine equipment are being familiar and accepted by the majority of plate processing enterprises. With its […]