Sheet metal powder spray, often referred to as powder coating, is a finishing process in which a dry, powdered paint is applied to a metal surface. The powder is typically applied electrostatically and then cured under heat to form a hard, durable finish. Here’s an overview of the process and its benefits:

Powder Coating Process

- Preparation:

- Cleaning: The sheet metal parts are cleaned to remove any dirt, oil, or oxidation. This is usually done using a chemical wash or abrasive blasting.

- Pre-treatment: Sometimes, a pre-treatment layer is applied to improve adhesion and corrosion resistance.

- Application:

- Electrostatic Spraying: The powdered paint is applied using a spray gun that imparts an electrostatic charge to the powder particles. The charged particles are attracted to the grounded sheet metal part, ensuring even coverage.

- Fluidized Bed Coating: The part is preheated and then dipped into a bed of fluidized powder, which melts and coats the part.

- Curing:

- The coated part is placed in an oven where the powder melts, flows, and chemically reacts to form a hard, continuous coating. The curing temperature and time vary depending on the type of powder used.

Benefits of Powder Coating

- Durability: Powder coatings are highly resistant to chipping, scratching, fading, and wearing compared to traditional liquid paints.

- Environmental Impact: Powder coating produces less hazardous waste than traditional liquid coatings and does not contain solvents or release volatile organic compounds (VOCs).

- Finish Variety: A wide range of colors and textures is available, including glossy, matte, metallic, and clear finishes.

- Efficiency: Over-sprayed powder can be recycled, which makes the process more cost-effective and minimizes waste.

- Protection: Provides excellent protection against corrosion, chemicals, and weather conditions.

Applications

Powder coating is used in various industries, including automotive, appliance, architecture, furniture, and general manufacturing, due to its durability and aesthetic appeal.

Considerations

- Thickness: Powder coatings can sometimes be thicker than liquid coatings, which may not be suitable for parts requiring very thin finishes.

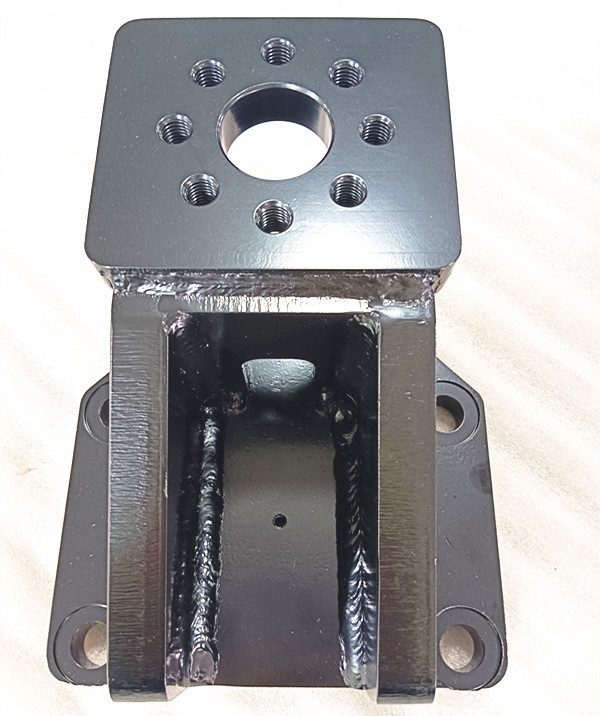

- Complex Shapes: While powder coating is effective on flat and simple shapes, very intricate parts might require special handling to ensure complete coverage.

- Initial Cost: The setup and equipment cost for powder coating can be higher than traditional painting methods, although operational costs may be lower over time.

Is there a specific aspect of sheet metal powder spray you’re interested in or any particular questions you have about the process?

china sheet metal fabrication manufacturers | sheet metal fabrication company china | china sheet metal fabrication companies | china sheet metal forming manufacturers | china sheet metal fabrication factory | china metal enclosure manufacturers | china sheet metal fabrication supplier | china custom sheet metal parts | china sheet metal parts company | china precision sheet metal manufacturer | china sheet metal enclosure fabrication | china sheet metal parts manufacturers | china sheet metal manufacturing manufacturers | Folded Sheet Metal Box

Leave a Reply