Tag: sheet metal fabrication

-

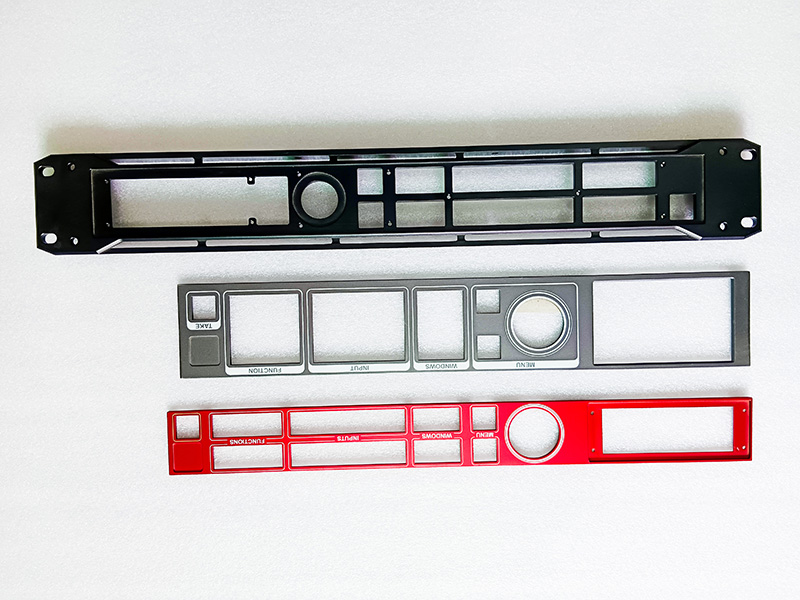

Characteristics and advantages of sheet metal design

First of all, we need to know what is sheet metal? The remarkable feature of sheet metal is that the thickness of the same part is the same. According to the definition, sheet metal is a cold working process of sheet metal, including shearing, punching / cutting / compounding, folding, riveting, splicing, forming (such as […]

-

Hydraulic sheet metal bending machine

The bending radius of sheet metal is a value required in the sheet metal drawing, which is difficult to determine in actual processing. In fact, the bending radius of the sheet metal is related to the material thickness, the pressure of the NC bending machine and the width of the lower die groove of the […]

-

How to determine the bending sequence of sheet metal bending?

General bending sequence Short side first and then long side: Generally speaking, when there are bends on all four sides, the short side first and then the long side is conducive to the processing of workpieces and the assembly of bending molds. First the periphery and then the middle: under normal circumstances, it is generally […]

-

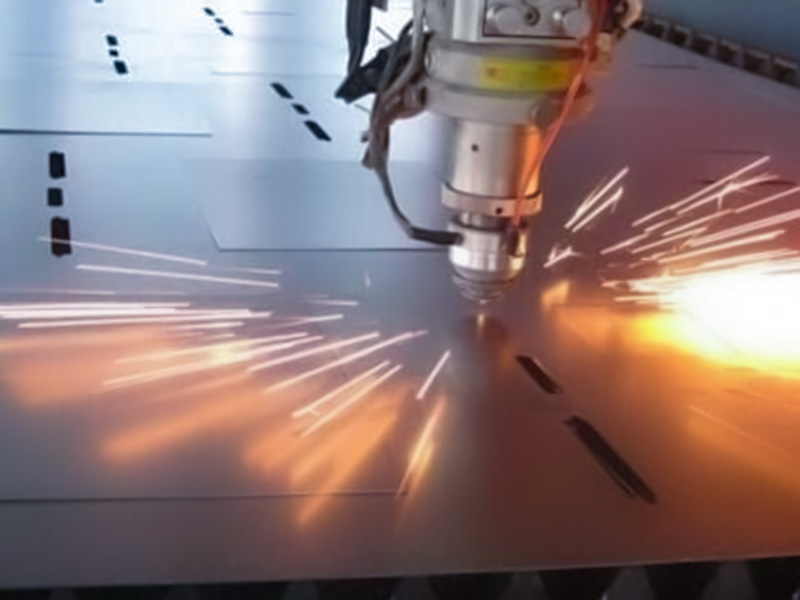

Process of sheet metal parts from making to forming

1、 Blanking. After the drawing is successful, the blanking methods shall be determined according to the expansion drawing, batch gap and technical requirements, including laser, CNC punch, plate shearing, die and so on. The NC punch is affected by the cutting tool. For the processing of some special-shaped workpieces and irregular holes, it should take […]

-

Four basic cold processing links to optimize sheet metal design

Generally, sheet metal parts have obvious advantages in strength, weight and cost, and have better point-to-point performance than traditional parts. Therefore, up to now, sheet metal parts have been gradually applied in China’s high-tech fields such as electronics and communication. At the same time, people have gradually put forward higher requirements for the quality and […]

-

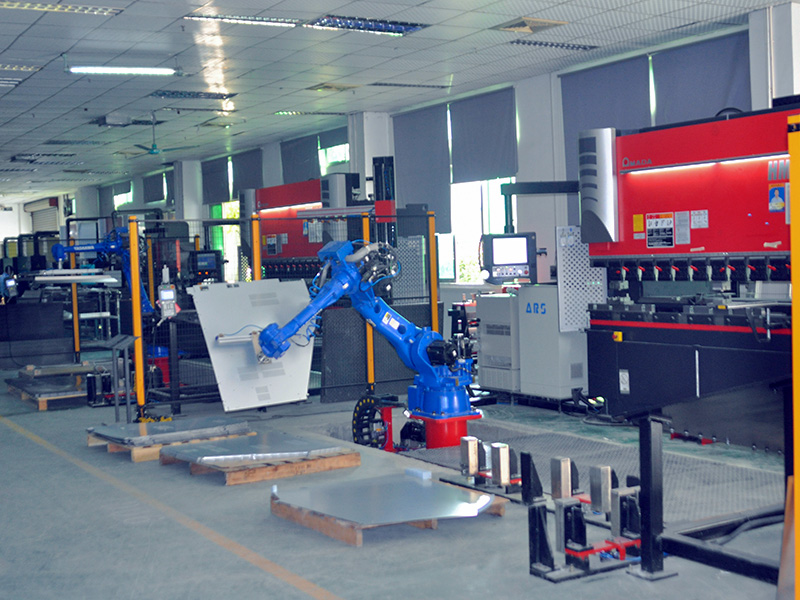

Common processes in sheet metal processing

Sheet metal processing technology is a comprehensive cold processing technology of sheet metal processing. With the more and more extensive application of sheet metal parts, sheet metal processing technology has become a very important part in the process of product development. Designers need to master the process characteristics of sheet metal. On the one hand, […]

-

Sheet metal die classification

Classification according to process properties A die that separates material along a closed or open contour. Such as blanking die, punching die, cutting die, cutting die, trimming die, cutting die, etc. The bending die is a die that makes the blank or other blank bend and deform along a straight line (bending curve), so as […]

-

Fiber laser cutting machine

China has gradually become an international processing and manufacturing center, and the demand for metal processing is increasing. Generally speaking, the electrical control box and machine shell in the metal processing industry are sheet metal parts, so the demand for sheet metal processing capacity is also increasing; Subsequently, the complexity of the process is also […]

-

Common problems in bending process

Sheet metal processing manufacturers generally have many kinds of processes, and bending process is one of them, which is often used. Problems are inevitable in this processing process. Then I will introduce you how to solve the problems encountered in the bending process. There are many common problems in the bending process. Here are three […]

-

Sheet metal strength design

Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much smaller than its length. Due to its special geometry and small thickness, it has the advantages of small processing volume, light weight, easy cutting, standardized shape and so on. It can be used […]