Tag: sheet metal design

-

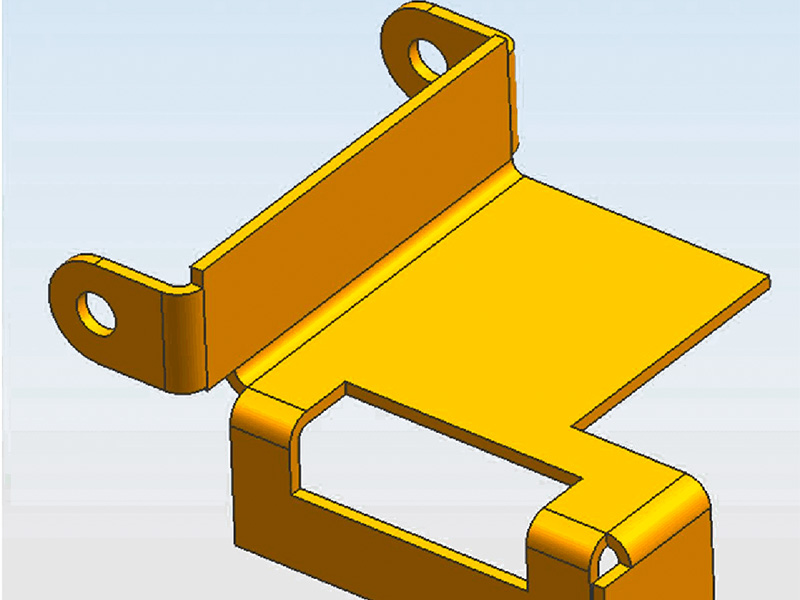

Basic principles of sheet metal product design

Sheet metal parts refer to sheet metal parts, which can be processed by stamping, bending, stretching and other means. A general definition is the parts with constant thickness in the processing process. For any sheet metal part, it has a certain processing process, which is the so-called process flow. The following describes the basic process […]

-

The design of sheet metal shell

For sheet metal equipment, the design of its sheet metal shell is limited by many factors and needs to meet many technical requirements. Specifically, the sheet metal shell is made of sheet metal materials. It is a box and shell made by sheet metal forming process to store servers, computers, power or other equipment, such […]

-

Bending problems to be considered in sheet metal design

The design needs to consider what is processing before forming and what is processing after forming. Considering that in the process of work production, some holes must be bent first and then processed: round holes, square holes, waist round holes, threads, etc. close to the bending edge need to be processed during blanking. If the […]

-

Process analysis of sheet metal structure design

Sheet metal processing is a comprehensive cold working process for sheet metal, including shearing, punching, cutting, folding, welding, riveting, etc. its remarkable feature is that the thickness of the same part is the same. Sheet metal is generally some sheet metal through manual or die stamping to produce plastic deformation to form the desired shape […]