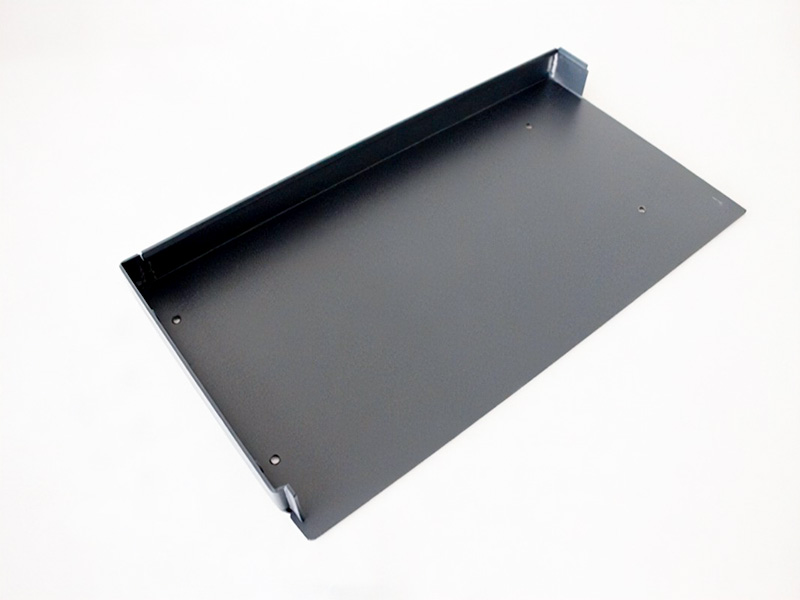

Tag: sheet metal chassis

-

Improvement measures for sheet metal processing

1 Material selection of sheet metal Sheet metal processing is generally used in the shell of equipment, so the selection of sheet metal is very important. We should not only select the appropriate and convenient processing, but also reduce the processing cost on the premise of ensuring the strength. When processing materials in the same […]

-

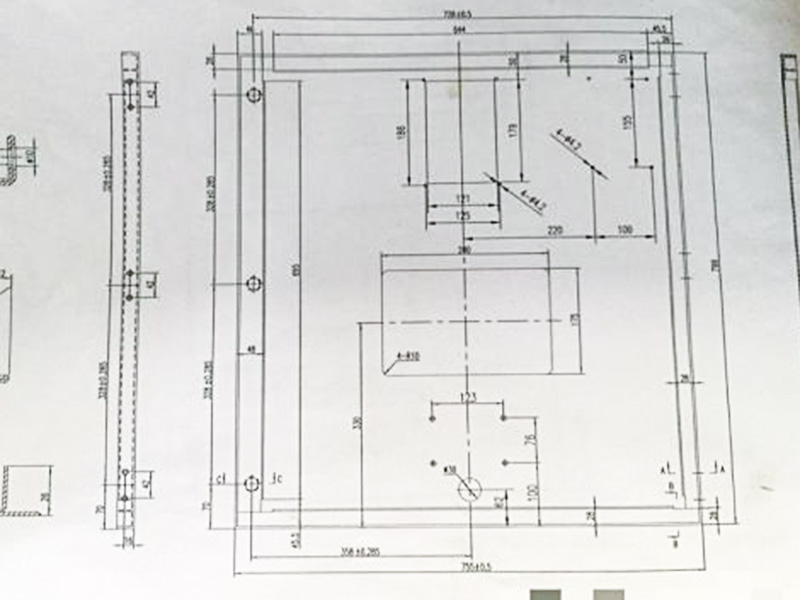

Sheet metal drawing planning

Some old group of sheet metal processing engineers like to use AutoCAD as the planning software of sheet metal chassis cabinet sheet metal part product model, and introduce parametric skills. The features have the nature of parameterization, and their features are expressed in the way of parameters. Engineers establish a feature library in advance, which […]

-

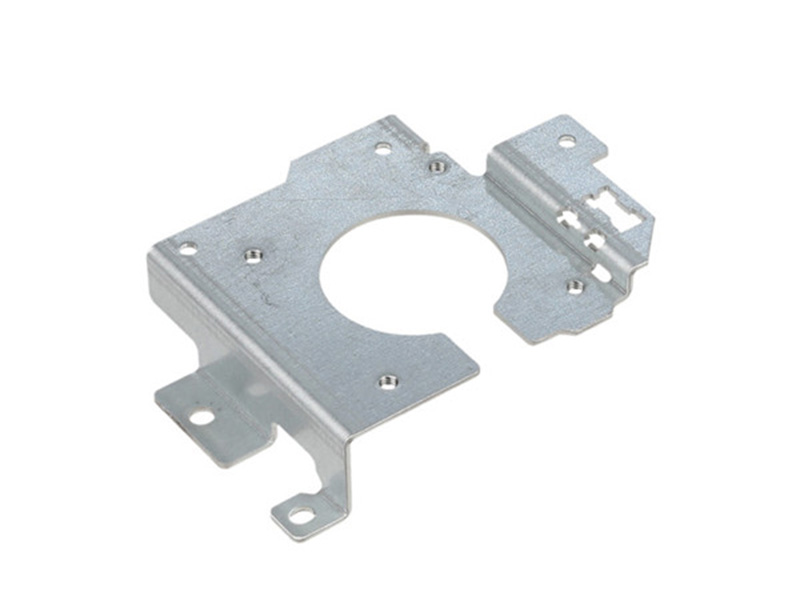

The design of sheet metal shell

For sheet metal equipment, the design of its sheet metal shell is limited by many factors and needs to meet many technical requirements. Specifically, the sheet metal shell is made of sheet metal materials. It is a box and shell made by sheet metal forming process to store servers, computers, power or other equipment, such […]

-

Design criteria of sheet metal structure

According to the problems encountered in the actual machining process, the problems needing attention in the structural design of sheet metal are discussed from the following aspects, and the corresponding design criteria are given. Selection criteria of sheet metal materials Sheet metal is generally used for the installation of equipment shell and electrical circuit, so […]

-

Wire drawing

Wire drawing can be made into straight lines, random lines, threads, ripples and spiral lines according to the needs of decoration. Straight line wire drawing refers to machining straight lines on the surface of aluminum plate by mechanical friction. The utility model has the dual functions of removing scratches on the surface of aluminum plate […]

-

Surface treatment of aluminum – oxidation and anodizing

Aluminum oxide (coloring) Aluminum and aluminum alloys are more and more widely used because they are easy to form and lighter than other metal materials. The chemical properties of aluminum and aluminum alloy are very active, so certain protective treatment must be carried out: such as electroplating, spraying, organic protection and oxidation treatment. Oxidation treatment […]

-

Development and application of sheet metal manufacturing industry

Sheet metal manufacturing is the blanking or cold and hot forming of sheet metal materials, aluminum profiles and pipe fittings without changing their cross-sectional characteristics. Then the assembly is carried out by means of electric welding, riveting and screw connection, and the production and manufacturing mode of the specified metal structure is produced. The key […]

-

Difficulties in aluminum welding

Very easy to oxidize. In the air, aluminum is easily combined with oxidation to form a dense aluminum oxide film (about 0.1-0.2um thick) , the melting point is high (about 2050 ℃), far exceeding the melting point of aluminum and aluminum alloys (about 600 ℃). The density of alumina is 3.95-4.10g/cm3, about 1.4 times that […]