Tag: Sheet metal

-

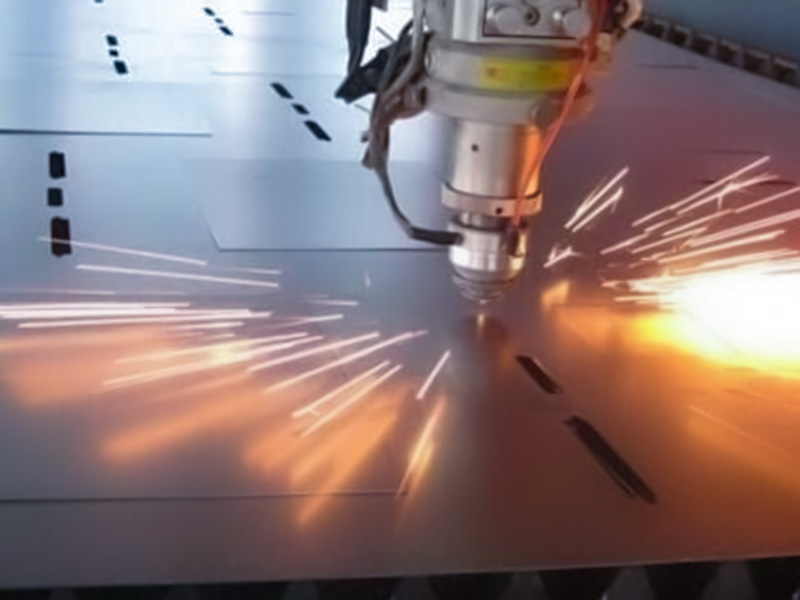

Process of sheet metal parts from making to forming

1、 Blanking. After the drawing is successful, the blanking methods shall be determined according to the expansion drawing, batch gap and technical requirements, including laser, CNC punch, plate shearing, die and so on. The NC punch is affected by the cutting tool. For the processing of some special-shaped workpieces and irregular holes, it should take […]

-

Four basic cold processing links to optimize sheet metal design

Generally, sheet metal parts have obvious advantages in strength, weight and cost, and have better point-to-point performance than traditional parts. Therefore, up to now, sheet metal parts have been gradually applied in China’s high-tech fields such as electronics and communication. At the same time, people have gradually put forward higher requirements for the quality and […]

-

Sheet metal forming processes

Sheet metal (usually steel or aluminum) plays an important role in construction and manufacturing. In the construction industry, it is used as a building and shell or roof; In the manufacturing industry, sheet metal is used for auto parts, heavy machinery, etc. When manufacturing sheet metal parts, manufacturers often use the following forming processes. Crimping […]

-

Basic principles of sheet metal product design

Sheet metal parts refer to sheet metal parts, which can be processed by stamping, bending, stretching and other means. A general definition is the parts with constant thickness in the processing process. For any sheet metal part, it has a certain processing process, which is the so-called process flow. The following describes the basic process […]

-

Causes of burr production

Causes of burr production in hardware stamping parts(Sheet metal parts) 1.The first possible reason is that the knife edge is blunt. Burr will be produced when the cutting edge is worn, blunt or gnawed. The factors affecting the blunt edge are: 1)It is not lubricated in time during operation, resulting in rapid wear; 2)Didn’t grind […]