Tag: China Sheet Metal Fabrication Factory

-

What are the different types of sheet metal welding?

Sheet metal welding involves joining thin sheets of metal using various welding techniques. The choice of welding method depends on factors such as the type of metal, the thickness of the sheet, and the desired strength of the weld. Here are some common types of sheet metal welding: 1. Tungsten Inert Gas (TIG) Welding Description: […]

-

How do you manufacture sheet metal parts?

Manufacturing sheet metal parts involves several processes that transform flat sheets of metal into usable components. These processes may vary depending on the complexity of the design, the type of metal, and the required precision. Here’s a general overview of how sheet metal parts are manufactured: 1. Material Selection Metal Type: Common metals include steel, […]

-

What is the most important thing in welding?

The most important thing in welding is achieving a strong, high-quality weld. A successful weld ensures that the materials being joined are securely bonded, capable of withstanding stress, and free from defects. To achieve this, several factors must be considered: Proper Technique: The welder must apply the correct welding technique for the materials and type […]

-

What welding is used for sheet metal?

Several welding methods can be used for sheet metal, depending on the thickness, material, and application. The most common welding techniques for sheet metal include: 1. TIG Welding (Tungsten Inert Gas) Best for: Thin sheet metal and non-ferrous metals like aluminum, magnesium, and copper. Advantages: Precise control, high-quality welds with minimal distortion. Disadvantages: Slower and […]

-

What does a sheet metal fabricator do?

A sheet metal fabricator is a skilled tradesperson who works with thin sheets of metal to create various structures and components. Their job involves cutting, shaping, bending, and assembling metal sheets into products or parts used in construction, manufacturing, and other industries. Here are some key tasks a sheet metal fabricator typically performs: Measuring and […]

-

What are the benefits of using a sheet metal enclosure?

Sheet metal enclosures offer several benefits that make them a popular choice for housing various types of equipment, electronics, and machinery. Here are some key advantages: 1. Durability and Strength Impact Resistance: Sheet metal enclosures are highly durable and resistant to physical impact, which helps protect the contents from damage. Corrosion Resistance: Depending on the […]

-

Sheet Metal Enclosure Design Tips

Designing a sheet metal enclosure requires attention to detail and consideration of various factors to ensure the final product is functional, manufacturable, and cost-effective. Here are some key tips to guide you through the process: 1. Material Selection Choose the right material: Common materials include aluminum, stainless steel, and cold-rolled steel. Each has its strengths, […]

-

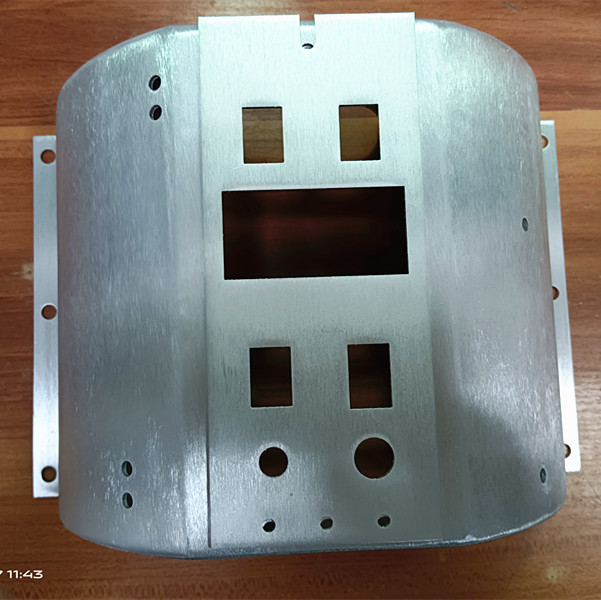

How are metal enclosures made?

There are three main processes: cutting, bending and assembly. Other processes include punching, folding and stretching. Sheet metal fabrication is a common manufacturing method for enclosures within computers. Metal enclosures are commonly used in various industries to protect electronic components, machinery, and other equipment. The manufacturing process involves several steps, from material selection to final assembly. […]

-

How to make sheet metal parts cheaper?

Are you looking for ways to reduce costs in the manufacturing process, or are you exploring material and design changes? To make sheet metal parts cheaper, consider optimizing your design for minimal material use, using standard sizes to reduce waste, and choosing cost-effective materials. Additionally, streamlining the manufacturing process and increasing production volume can lower […]

-

How do you manufacture sheet metal parts?

Manufacturing sheet metal parts involves several key processes, each suited for different types of parts and applications. Here’s an overview of the common methods: 1. Design and Planning CAD Design: Start with a Computer-Aided Design (CAD) model of the part. This model helps visualize the final product and plan the necessary processes. Material Selection: Choose […]