https://www.sheetmetalxj.com/

JIATONG XJ Precision Sheet Metal Fabrication

-

Sheet Metal Enclosure Design Tips

Designing a sheet metal enclosure requires attention to detail and consideration of various factors to ensure the final product is functional, manufacturable, and cost-effective. Here are some key tips to guide you through the process: 1. Material Selection Choose the right material: Common materials include aluminum, stainless steel, and cold-rolled steel. Each has its strengths, […]

-

What are the rules for electrical enclosures?

Electrical enclosures must adhere to various standards and regulations to ensure safety, functionality, and durability. The rules for electrical enclosures are primarily governed by organizations like the National Electrical Manufacturers Association (NEMA), International Electrotechnical Commission (IEC), and Underwriters Laboratories (UL). Here’s an overview of key considerations: 1. NEMA Ratings (USA) NEMA Standards: NEMA provides standards […]

-

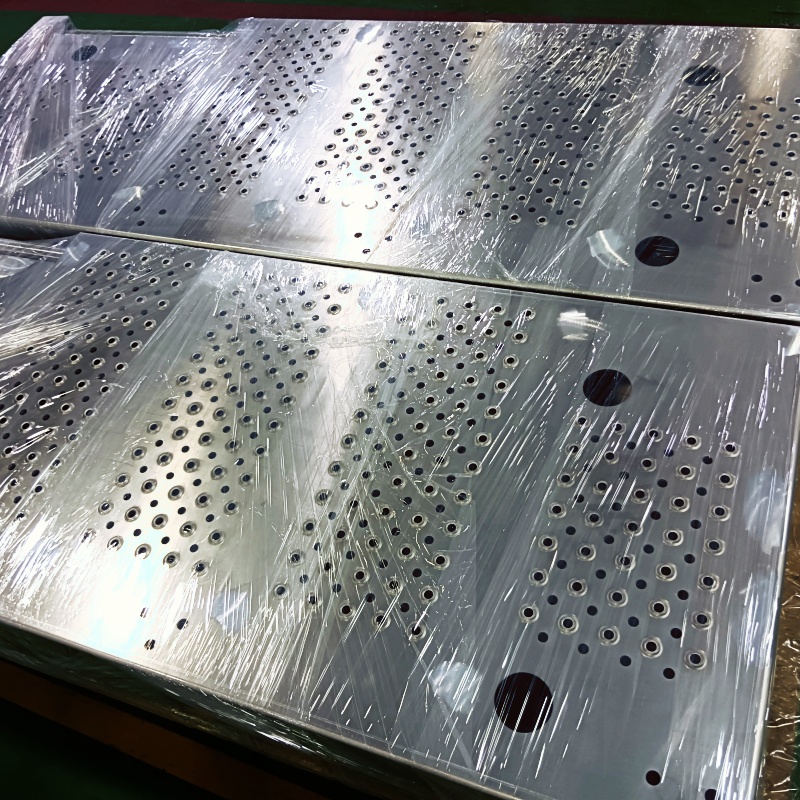

How are metal enclosures made?

There are three main processes: cutting, bending and assembly. Other processes include punching, folding and stretching. Sheet metal fabrication is a common manufacturing method for enclosures within computers. Metal enclosures are commonly used in various industries to protect electronic components, machinery, and other equipment. The manufacturing process involves several steps, from material selection to final assembly. […]

-

How to make sheet metal parts cheaper?

Are you looking for ways to reduce costs in the manufacturing process, or are you exploring material and design changes? To make sheet metal parts cheaper, consider optimizing your design for minimal material use, using standard sizes to reduce waste, and choosing cost-effective materials. Additionally, streamlining the manufacturing process and increasing production volume can lower […]

-

How do you manufacture sheet metal parts?

Manufacturing sheet metal parts involves several key processes, each suited for different types of parts and applications. Here’s an overview of the common methods: 1. Design and Planning CAD Design: Start with a Computer-Aided Design (CAD) model of the part. This model helps visualize the final product and plan the necessary processes. Material Selection: Choose […]

-

Is e-coating better than powder coating?

E-coating and powder coating are both widely used finishing processes that provide protective and decorative coatings on metal surfaces. Each has its strengths and is better suited for specific applications depending on factors like material, environment, desired finish, and budget. Here’s a comparison of the two processes: 1. Process Overview E-Coating (Electrophoretic Coating): Involves immersing […]

-

What is the best aluminum for enclosures?

Selecting the best aluminum for enclosures depends on various factors such as the specific application, environmental conditions, and desired properties. Here are some commonly used aluminum alloys for enclosures along with their characteristics: What is the best material for an enclosure? The best material for an enclosure depends on its intended use. Metals like stainless steel […]

-

What is the best welding wire for sheet metal?

An ER70S-6 solid wire is the most common choice for welding mild steel. For welding sheet metal, particularly mild steel, the best welding wire is typically an ER70S-6 MIG (Metal Inert Gas) wire. Here are some reasons why ER70S-6 is often preferred for this application: Versatility: ER70S-6 is suitable for a wide range of sheet […]

-

What is the difference between sheet metal fabrication and machining?

Sheet metal fabrication and machining are both manufacturing processes used to create metal parts, but they differ in their techniques, applications, and the types of materials they typically work with. Here are the key differences: Sheet Metal Fabrication: Material Form: Primarily works with thin, flat sheets of metal. Processes: Cutting: Shearing, laser cutting, plasma cutting, […]

-

China Sheet Metal Fabrication Manufacturers

Distinguishing a professional sheet metal fabrication manufacturer involves assessing several key factors: Experience and Expertise: Years in Business: Long-standing manufacturers tend to have more experience and proven track records. Specialization: Check if they specialize in the type of fabrication you need (e.g., automotive parts, electronics, construction). Certifications and Standards: ISO Certification: Look for ISO 9001 […]

Got any book recommendations?