Category: Technology News

-

What to do if Sheet Metal Parts are Easily Deformed?

Sheet metal parts are prone to deformation during the manufacturing process, which can result in parts that do not meet the expected specifications. Here are some solutions to prevent or correct deformation of sheet metal parts from Dongguan Jiatong Precision Hardware Products Co: Different materials have different strengths, and Jiatong will help prevent deformation or […]

-

How is the Chassis Polishing Process?

The process of polishing the undercarriage usually involves the following steps: Preparation: First the chassis is put through a thorough cleaning to remove any loose debris, dirt or grease, ensuring that the surface is clean and free of any contaminants that could interfere with the polishing process. Sanding: Depending on the condition of the chassis, […]

-

How the Bank Storage Machine Shell is Painted?

The process of painting the housing of a banknote storage machine usually consists of the following steps: The enclosure is first cleaned and prepared for painting. Any dirt, grease, or other contaminants y be removed to ensure a clean surface for the paint to adhere to. Any defects or rough spots on the housing are […]

-

How Sheet Metal Boxes are Manufactured?

The process of making a sheet metal box typically involves several steps, including cutting, bending, forming, and welding. Here is a general overview of the process: The box is first designed using computer-aided design (CAD) software, taking into account the required dimensions and specifications. The appropriate sheet metal material is chosen based on the intended […]

-

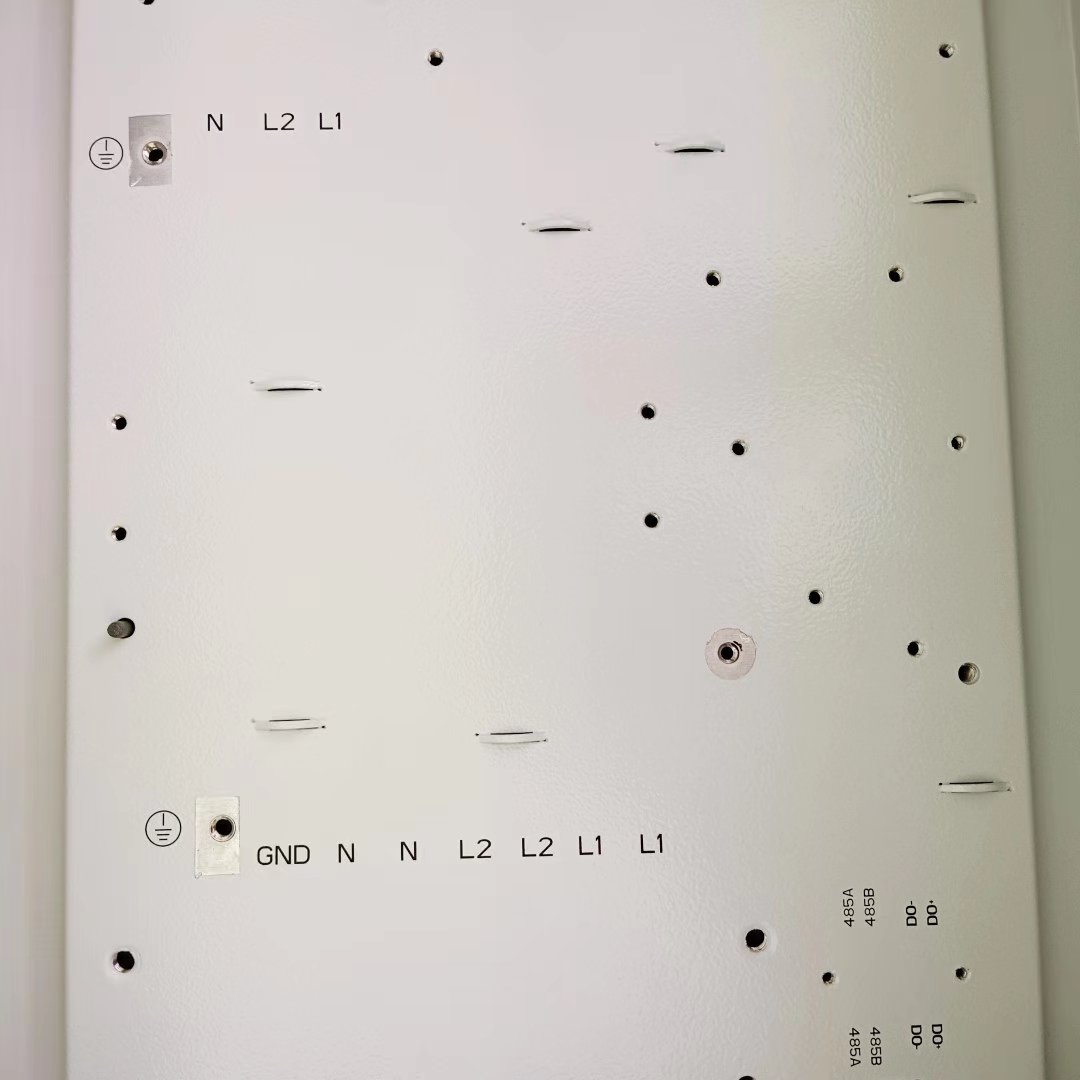

Outdoor EV Charger Enclosure Spray Process

Box surface spraying can protect the quality of the box itself anti-corrosion and other issues, but also can reflect the box is not the same beautiful role, so the professional spraying process is very important, the following take you to understand the charging pile shell process: 1, first of all, the sheet metal technicians will […]

-

Application of Aluminum Alloy Profiles on TVs

First, the use of aluminum profiles in decorative parts: As the middle frame of super-narrow, bezel-less TVs is bent with aluminum profile, if the decorative parts use the same metal material, it can avoid problems such as large assembly gaps brought by injection molding decorative parts, so the material of the lower frame of TVs […]

-

What Factors Affect the High Speed Cutting of Vertical Machining Center?

With the continuous development of the machining industry, highly complex curved workpieces and multi-process workpieces have become commonplace, and their refinement is becoming more and more demanding. However, high-speed cutting is different from ordinary cutting, and there are many factors affecting the final machining accuracy and surface quality of the workpiece. The following is a […]

-

What is the Finishing Process?

Currently, there is an increasing demand for sheet metal cabinets in various industries, mainly because they can play a good role in protecting electronic components. In order to ensure the quality of sheet metal cabinets in production, there is often some processing work to be done after forming. So do you know what processing needs […]

-

What is the Difference Between Plasma Cutting and Laser Cutting?

Laser cutting, which originated in the mid-1960s, is a cutting process characterized by the use of an amplified laser as the “tool” and a computer numerical control program to perform the cutting operation. The main lasers used in laser cutting are CO2, neodymium (Nd), yttrium aluminum garnet (Nd: YAG) and fiber optic lasers, all of […]

-

How to Choose the Right Material for the CNC Machined Parts?

1、Whether the rigidity of the material is sufficient Rigidity is the primary consideration when choosing materials, because the product needs a certain stability and wear resistance in the actual work, the rigidity of the material determines the feasibility of product design. According to the characteristics of the industry, non-standard tooling design, usually choose 45 steel […]