Month: April 2022

-

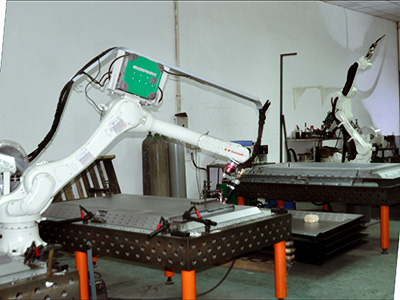

Arc welding technology

Arc welding technology is divided into six welding methods: manual arc welding, submerged arc welding, gas tungsten arc welding, gas metal arc welding, plasma arc welding and tubular wire arc welding. The following is the introduction of these six different welding methods: 1.Manual arc welding Manual arc welding is one of the earliest and still […]

-

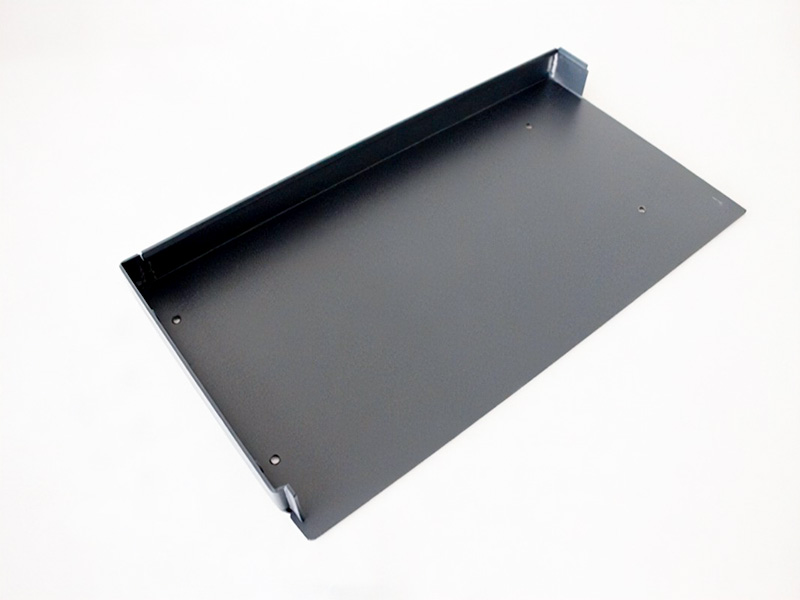

Some bending methods

1)Suspended bending (also called three-point bending) The punch presses the workpiece into the die without pressing it against the die wall. When the punch core moves down, the edge of the workpiece bends upward and forms an included angle. The deeper the punch presses the workpiece into the die, the smaller the angle. At this […]